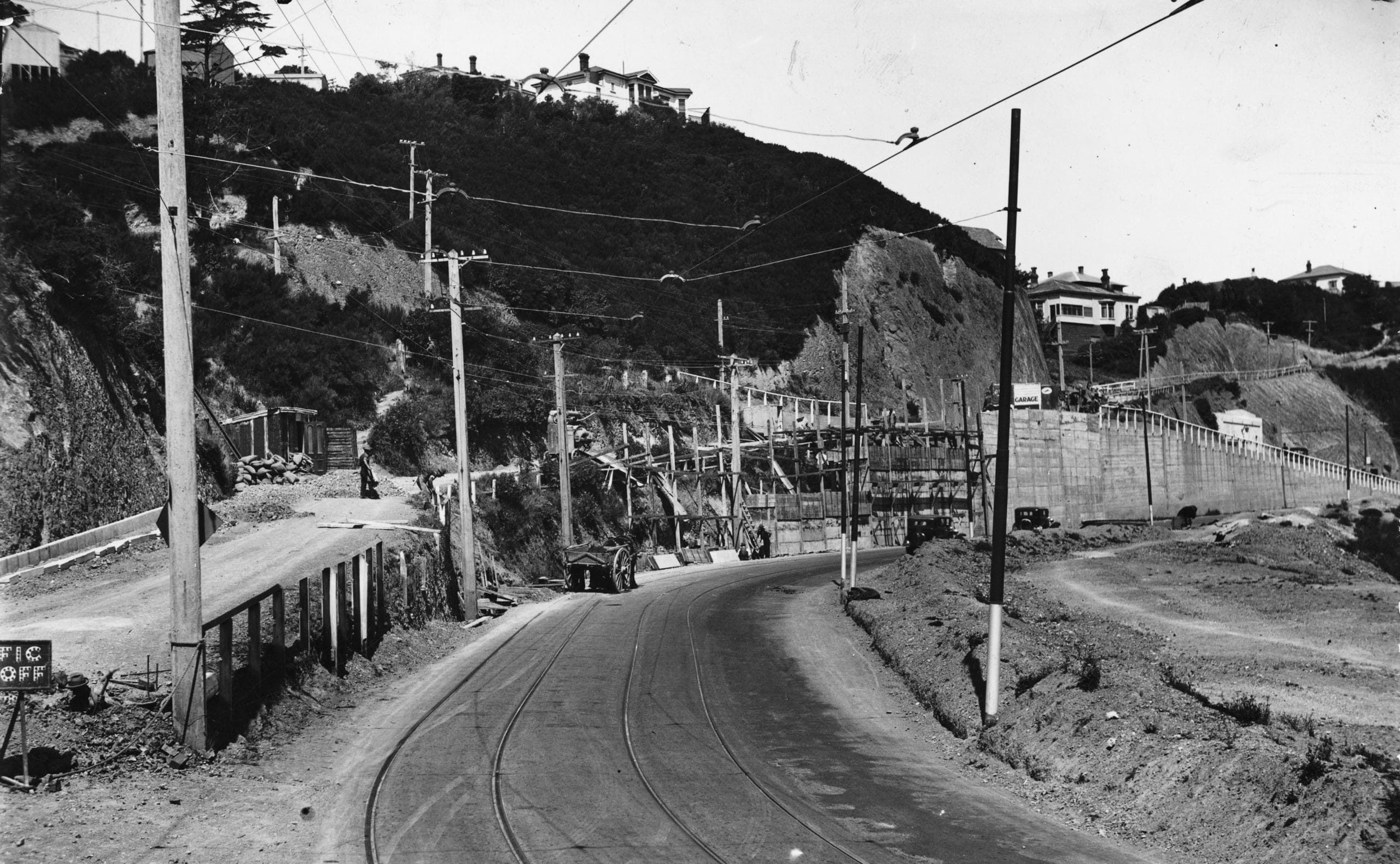

A black and white photo from the 1920s shows the steep challenge involved to construct the original Chaytor Street retaining wall, part of a main arterial route in New Zealand’s capital city, Wellington.

Over a century later, engineers from WSP New Zealand, a renowned design, engineering and environmental services consultancy, in collaboration with the Wellington City Council, have tackled the tricky task of modernising this historic landmark for earthquake resilience.

Though today, it’s with the latest in geotechnical modelling technology at their fingertips.

The Chaytor Street retaining wall supports a sharp embankment adjacent to a deep, in-filled gully, providing vital access from the central city to some of Wellingtons largest suburbs, including Karori, Wilton and Northland. (Image credit: Alexander Turnbull Library, Wellington, NZ).

“We’ve developed a resilience-based design to reinforce the wall and address the vital overarching challenges of risk, safety and accessibility,” says Pathmanathan Brabhaharan, National Technical Director (Geotechnical Engineering and Resilience) at WSP.

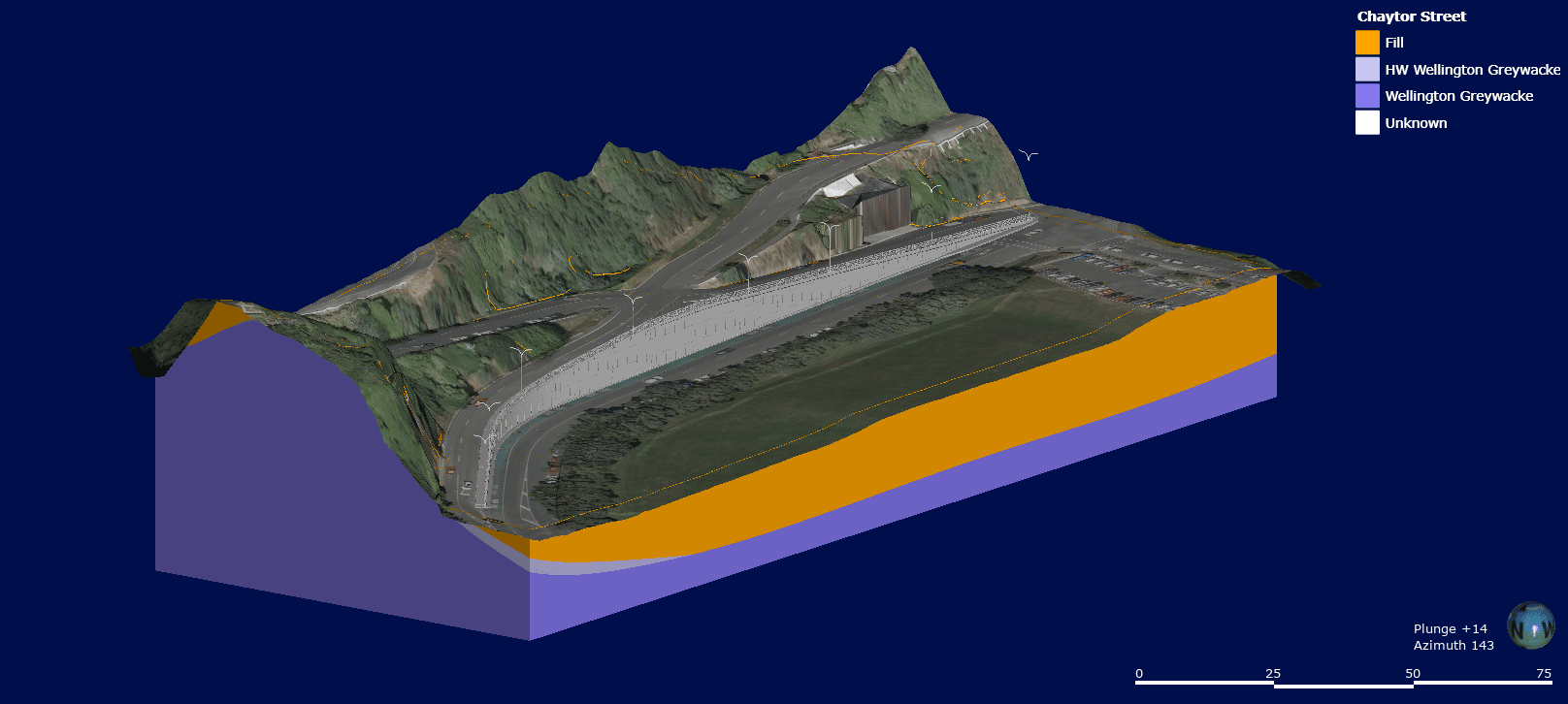

In a stroke of genius, WSP engineers have integrated the Revit design of the structure with new and vintage subsurface geotechnical data, together with topographical data, to create a robust, interactive 3D model.

“A solution that easily visualises the intricate engineering required for the job,” says Siva Arumugam, Senior Geotechnical Engineer, WSP, who managed the design.

But – even with innovative digital technology in the toolbelt – building an accurate geological model was not without its challenges.

The popular landmark is embedded in the community’s psyche – there would be few Wellingtonians who have not driven, cycled or walked by, taking in the quirky artworks. (Image credit: Brabhaharan, WSP).

A unique set of challenges

At 200 metres long and up to 7.5 metres high, Wellington’s Chaytor Street retaining wall looms large. Much like the task of designing contemporary engineering for an existing structure.

“One important aspect of this retrofit project that most could easily miss is the fact we’re working with two expansive walls – not one – constructed in different ways, at different times and adding quite a bit of complexity to the data,” says Jordan Miers, WSP Geotechnical Technician.

“It’s always very interesting working with historical investigations and inherited data, we have to assess its reliability. And if there are two conflicting pieces of data – which should we go with? It may not necessarily be the one that supports our assumptions,” says Miers.

When integrating Revit into Leapfrog Works to establish his 3D model, Miers was intrigued to see how the two might mesh and what could be accomplished.

“We hit a real scalability issue in our conversion – actually quite an entertaining one!” says Miers.

Revit is a BIM software programme designed to work in millimetre units, whereas the subsurface mapping capabilities of Leapfrog operate in metres.

“Initially, our five-metre coordinates were imported as 5000 units – completely blowing our order of magnitude. We had ourselves a giant wall model towering over a tiny ground model.”

“With a conversion to consistent coordinates and by exporting the Revit data into a DWG file before it was imported, it all worked out,” says Miers.

A busy roadway and bus lane hug the wall base below with two roads, Raroa Crescent and Northland Tunnel Road, intersecting above. (Image credit: Miers, WSP).

Collaboration is crucial

WSP colleagues Arumugam and Miers both agree certain technical aspects of this project proved very demanding – yet satisfying – to solve.

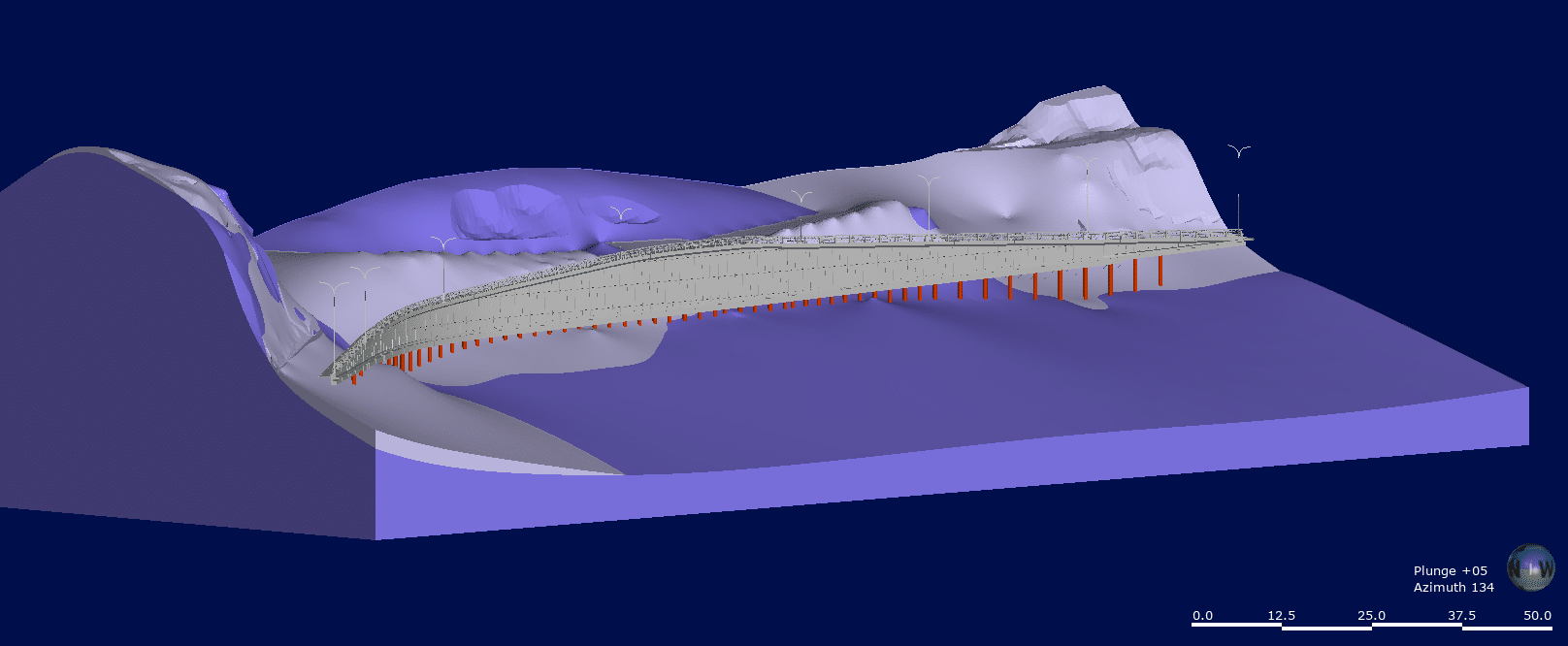

“To achieve the required level of seismic performance we engineered the retaining wall to have over 100 steel reinforcing rock anchors socketed into the bedrock at different angles,” says Arumugam.

A slope stability analysis in GeoStudio was used to assess the wall, built on fill overlying a greywacke bedrock edge that undulates to follow the steep contours of the site, with rock condition dependent on surface proximity or groundwater infiltration.

3D models help interpret these geological variations to better inform decisions, such as the expected drill depth to viable bedrock and the balance of anchors and piles to optimise the construction cost.

“The geotechnical models we’ve created allow us to visualise the subterranean aspects more easily to help solve any design problems as well as implement the rock anchors and piles as accurately, efficiently and cost-effectively as we can,” says Arumugam.

“It’s taken absolute teamwork, a collaboration of geophysics and drilling investigation contractors, a Manilla based Revit technician, designers based in our Wellington WSP office and the expertise of Miers in the geotechnical space. We’ve enjoyed seeing it all come together.”

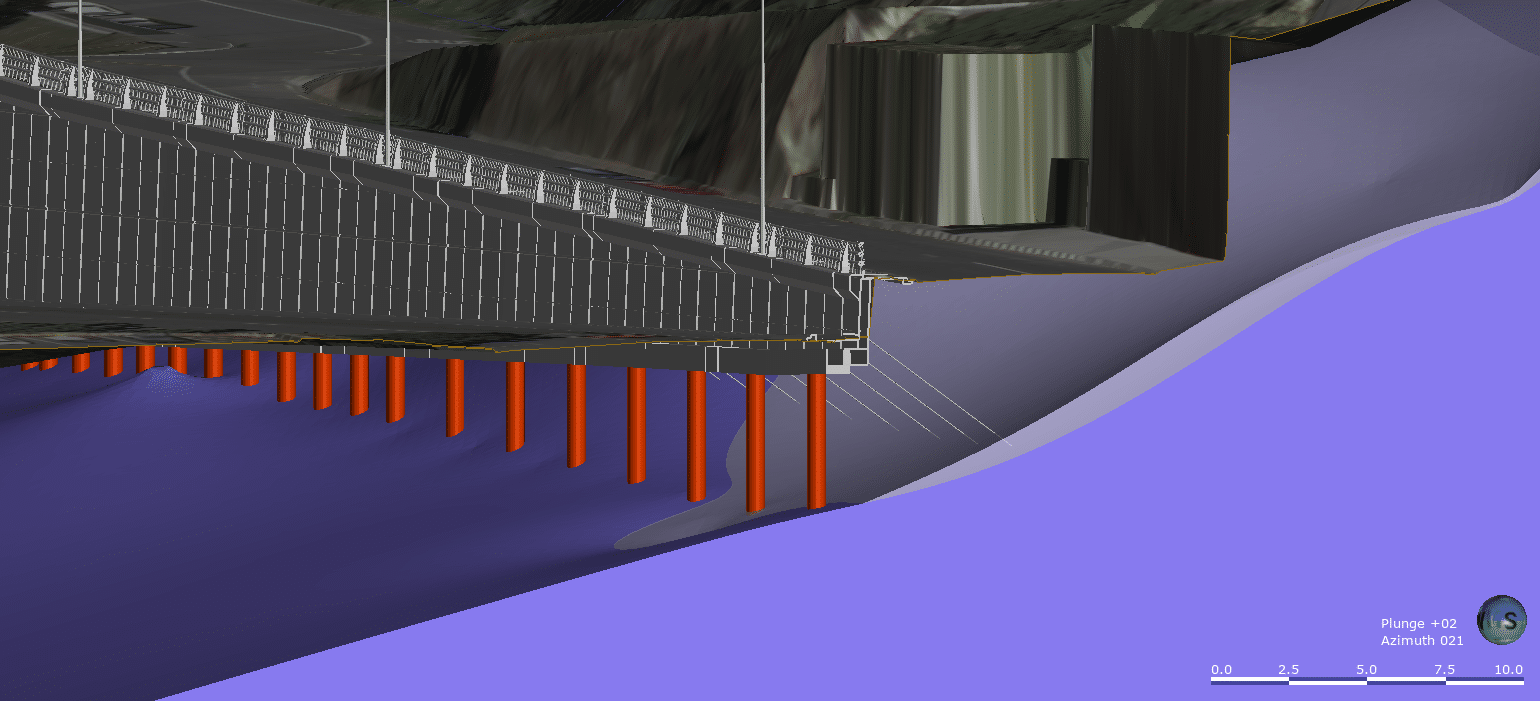

The geological 3D model shows piles penetrating deeper at the structure’s centre where the bedrock edge recedes. Dark purple represents stronger material with light as weaker or more weathered. (Image credit: Miers, WSP).

Showcasing the digital twin design.

WSP is working in collaboration with the Wellington City Council on the project, as part of the region’s ongoing programme to help ensure major transport structure assets including retaining walls, tunnels, and bridges are more seismically resilient.

Simplifying complex data into a 3D visualised solution gives crucial insight to those stakeholders without engineering expertise, to better understand the complexities of the project.

“There’s real value in being able to showcase the design details and share what the wall will look like after the earthquake strengthening is complete,” says Miers.

The 3D model – or digital twin – can be manipulated to display the wall at different angles, view a sectioned slice, pin down details of the rockhead anchors, where the structure fits in relation to the road network and existing utilities, the new vehicle safety barrier, lighting and more.

“It’s an excellent tool for explaining certain geological features and, with the capacity to run multiple geological models, is critical to communicating one of the biggest variables – risk – to clients as well.”

“We can even share the final touches by draping the Council commissioned Māori and native bird inspired architectural features across the wall’s concrete overlay,” says Miers.

Piles along the length of the retaining wall and steel reinforcing rock anchors installed at angles into the steep topography complete the engineering required for optimal seismic performance. (Image credit: Miers, WSP).

A digital landmark legacy

The beauty of creating a dynamic, future-proofed digital twin is beyond skin deep.

“Leapfrog is a powerful tool to interpolate data and our interpretive model will provide a solid estimate for the construction phase,” says Miers. “And we can continuously monitor and refine our representation with any variations in ground conditions found on site.”

A constantly updating model delivers a comprehensive, long term asset management tool for the Wellington City Council and its community as well as enhanced safety for decades to come.

Brabhaharan’s extensive career in earthquake engineering has taken him to many seismic hotspots across the globe. He has witnessed first-hand the devastation a major event can cause to communities and infrastructure.

“The Chaytor Street retaining wall is part of a very high-profile section of road where many people travel – every day,” he says. “With engineered, robust reinforcement it will be strong, aesthetically beautiful, safer and most importantly, more resilient in an earthquake – for me, this is the ultimate benefit.”