The trouble with tradition

A traditional method for ERW (Explosive Remnants of War) and UXO (Unexploded Ordnance) detection is an analogue survey known as “mag and flag”. It’s a fast and cheap process adopted as a cost-effective way to increase the safety of at risk communities and to clear former war zones and bombing ranges. But it’s far from perfect.

“Mag and flag” methods utilize metal detectors to identify if ferrous or non-ferrous metal is present. These instruments are similar to a consumer grade metal detector that a civilian might use on a beach. When the operator interprets the audio, visual, or motion alarm signal, they place a flag in the ground to identify the potential danger. The trouble with “mag and flag” is myriad:

- Success depends on the operator

- No auditable digital data recorded

- Possibility of missed targets

- Cannot distinguish between ordnance and metal debris

- High false alarm rate

- Instrument malfunctions

- Magnetic soils can impact readings

Given the high false alarm rate, the risk is that communities need to be evacuated unnecessarily, and resources must be tied up identifying potential targets that turn out to just be debris. On the other hand, soil conditions and operator error can risk leaving UXO in the ground, placing communities at undue risk.

The benefits of digital

Digital geophysics for UXO surveys have been documented to drastically reduce the number of unidentified UXO. These surveys enhance detection accuracy by providing a detailed record of survey coverage, as well as a historical archive. This record can be reviewed and reprocessed to ensure proper data collection, and can be corrected in the event of a survey problem.

Digital surveys allow the area to be analyzed for depth, size, and the nature of the target, helping to distinguish UXO from harmless scrap metal or magnetic components in the soil.

The US Department of Defense (DoD)

Previously, the DoD and the US Army Corps of Engineers (USACE) utilized the traditional “mag and flag” method to clean up their munition sites. The lack of accuracy provided by these analogue instruments meant that on most munition response sites, all metal objects had to be dug up in order to determine their risk level, including harmless scrap metal.

Highly trained UXO technicians had to extract hundreds of inert, non-hazardous items for every munition recovered.

The costs associated with this inefficiency were substantial, and limited budget and resources meant that the amount of acreage that could be examined had to be constrained.

Unnecessary area closures and evacuations affected the communities, and excessive digging disturbed local vegetation. DoD thus began utilizing digital geophysical sensors. Initially this began with magnetic surveys which measure magnetic susceptibility and are good at detecting ferromagnetic materials (eg. steel). While this was useful at detecting UXO, the surveys were still picking up scrap metal and fragments of bombs which could be left in the ground. Electromagnetic sensors were then utilized because of the additional insight this survey data could provide to estimate parameters about targets such as the depth and size.

Today, advanced electromagnetic induction (EMI) sensors have been designed specifically for finding and classifying buried metal. These multi-axis sensors provide rich data that measure intrinsic properties about the target source such as axial symmetry of the object, decay rate and magnitude of the response. This data is inverted to give insight about the object shape, wall thickness and physical size.

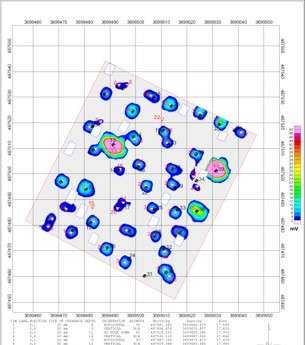

Munition items are typically symmetrical, thick-walled, and larger in size, as compared to non-UXO items. A classification decision is then made based on a comparison between the target “fingerprints” and a library of object parameters of known munition items. If the analysis indicates a target item that matches the description of a munition, it is extracted. If it is found to match the description of debris, it is left in the ground. In situations where the classification is inconclusive, the item is extracted and investigated, nonetheless.

This classification process has been demonstrated to show tremendous cost savings related to digging, and as a result advanced geophysical classification (AGC) is now mandated by the USACE on their munition response projects.

Seequent UXO classification solutions

Contractors understand that the key to a successful project lies in increasing efficiency and ensuring accuracy, while keeping costs down. Digital geophysical surveys can represent 10 – 100 Gbs of data/day when utilizing advanced electromagnetic sensors.

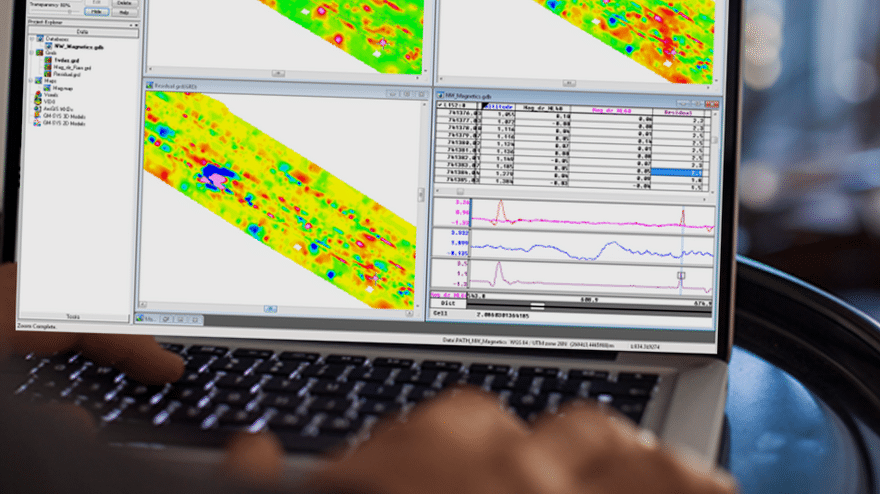

Specialized workflows in Seequent’s Oasis montaj, UXO Land/Marine, and UX-Analyze software were purpose-built to handle large volumes of geophysical munitions data and are changing the way UXO operations collect and analyze data, increasing accuracy and efficiency, and keeping projects on budget.

Here’s how Seequent’s solutions increase effectiveness for land and marine UXO surveys:

Industry-standard workflows – Seequent has partnered with thought leaders in munitions research, equipment manufacturers and the US Department of Defense to develop leading edge sophisticated UXO detection and classification techniques that are robust, fast, efficient and effective, allowing you to get your job done with speed and confidence, and differentiate your company to win projects.

Specialized data processing tools – Purpose-built tools to process large volumes of geophysical data for precise positioning of single sensors or sensor arrays, navigation corrections when working in marine environments, as well as the application of instrument corrections and filters to remove unwanted noise or signal from your data, and data quality control checks. This gives confidence in the accuracy of your target locations and the quality of your data.

Target picking and management tools – When working with hundreds or thousands of potential targets, tools that provide both automated and manual ways of selecting targets make target list management easy and fast.

Target analysis – Analysis tools for magnetic and electromagnetic anomalies provide calculations of estimated target locations and depths, apparent size and magnetic moment which help characterize UXO targets for informed decision-making. The automated inversion modelling supports the sparse data commonly seen in many marine magnetic and gradiometer surveys.

Classification of targets – when working with advanced electromagnetic induction (EMI) sensor data UX-Analyze provides streamlined workflows to enable classification and ranking of targets to separate munition items from clutter.

Data visualization – Display and present your data and targets as 1D profiles, 2D grids, or 3D views. Maps are also dynamically linked to the original data in the database to aid in interpretation of the results.

Scripting – Standard processing and data preparation routines can be captured and recorded as scripts to automate repetitive processes.

Audit record – In addition to target lists and maps, a historical archive record of data processing steps is captured for future reference.

Collaborate with stakeholders – Easily share and progress your results with team members and knowledge experts. Work together to better manage project risk, costs and timelines.

Technical Support – A global technical support network ensures you have uninterrupted access to the productivity tools you need – when you need them. Mission critical requirements are met, and issues are efficiently resolved, through our agent-assisted support and tiered support escalation.