In an industry striving for best practice in Tailings Storage Facility management, OceanaGold’s digital response to their Waihi operations offers a gold mine of information. With Bentley and Seequent’s innovative software, the team created a data-driven digital twin, to better understand the physical asset and help manage safety.

OceanaGold Corporation is an emerging multinational producer of gold, copper, and silver: minerals critical for renewable energy, transport, life-saving medical equipment, and the technology that connects global communities. With over 24 years of sustainable operations in New Zealand, OceanaGold’s Waihi operations received consent to develop the Martha Underground in early 2019, a project that extends the life of the mine and supports economic and social stability in the region.

Tailings Storge Facilities (TSFs) are typically designed, built and operated using manual observational methods, data comparison, and reporting processes. To better manage their Waihi Mine TSFs, Principal Geotechnical Engineer, Andre Alipate and the team, initiated this crucial pilot project to validate the use of digital solutions.

”Faced with vast amounts of siloed data, we sought to integrate data sets and develop a cloud-based digital twin to support collaborative, proactive monitoring of slope stability and to help ensure safety,

said Alipate.

The team selected Seequent Central, Leapfrog Geo, GeoStudio, and Bentley’s iTwin IoT to develop 3D geological and geotechnical models, and a digital twin within a dynamic, cloud-based environment, enabling digital monitoring and automated, consistent reporting.

“A digital twin evolves and grows over the life of a mine and becomes key for general and best practice management of tailings dams. A better understanding of how your TSF is being built, along with its performance and safety profiles, brings a shift in mindset from a reactive to more proactive approach,” said Alipate.

Fast Metrics:

- The town of Waihi, in New Zealand’s North Island, has a population of ~5800 people and a mining history that spans three centuries, after gold was first discovered in the 1800s.

- OceanaGold’s Waihi mine produces 50-60,000 ounces of gold per year, with an indicated resource of 2,000,000 ounces, and a life of mine of 6-7 years (based on current resources).

- Waihi is also renowned for its prosperous fruit and dairy industries, pristine rivers, beautiful coastlines and unique flora and fauna that hold significant cultural relevance to local iwi.

Andre Alipate, Principal Geotechnical Engineer at OceanaGold, spoke at the 2023 Bentley YII Going Digital Awards in Infrastructure, held in Singapore. (Image: Bentley)

Equipping TSF management teams to make more informed decisions

Geoscience data underpins every major decision made within the mining lifecycle. From exploration and production to mining, processing and tailings storage, right through to the restoration of mining-related infrastructure at the end of its tenure.

The value of a digital twin is that it supports dynamic updates, surpassing static 3D models. This enhances the way engineers visualise and interact with a TSF to better track changes, perform analyses, or inform decision-making.

”During the life of a mine, vast amounts of data are produced, which, if managed effectively, can enable new ways to solve increasingly complex problems. Having a digital workflow equips engineers and dam owners to easily condense, understand and analyse complex information, and uncover insights, in a very simple and accessible way,

said Alipate.

“As an example, after a significant rainfall event, we can closely monitor sensor readings from a section of our TSF to identify any changes, such as core pressure or groundwater levels in the structure, to manage risk or take action if needed,” said Alipate.

Data-driven insights also improve management and governance over the life cycle of an asset to enable faster, more informed decision-making, while upholding safety and productivity.

“Harnessing our existing technology to develop a digital twin powered by real-time IoT, provided a new set of tools for TSF governance, that align our Waihi operations with various domestic and international management standards,” said Alipate.

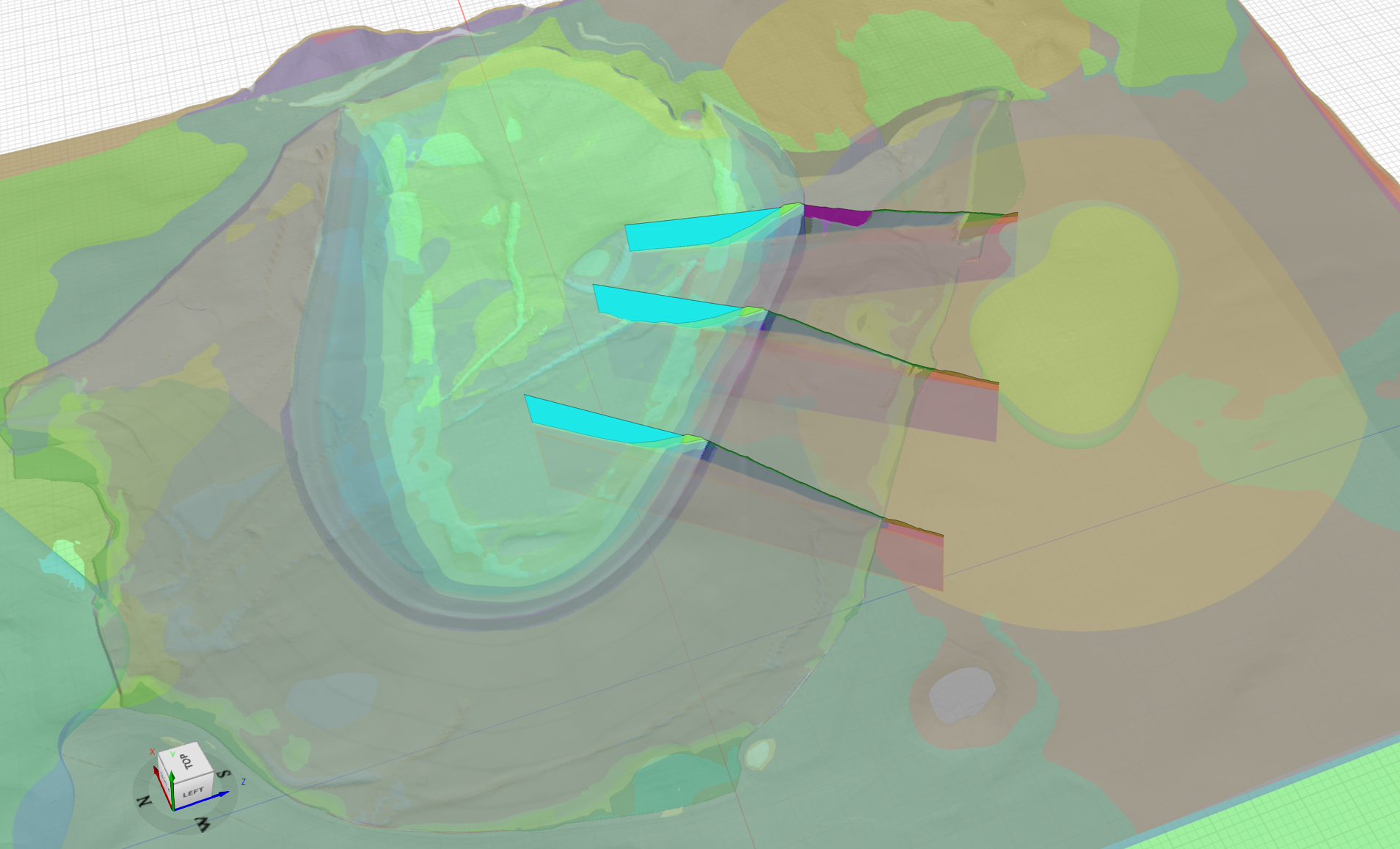

An integrated model with 2D cross sections spliced into the 3D model to show the Factor of Safety based on geotechnical analysis. (Image: OceanaGold)

Enhancing resilience and reducing risk with digital twin technology

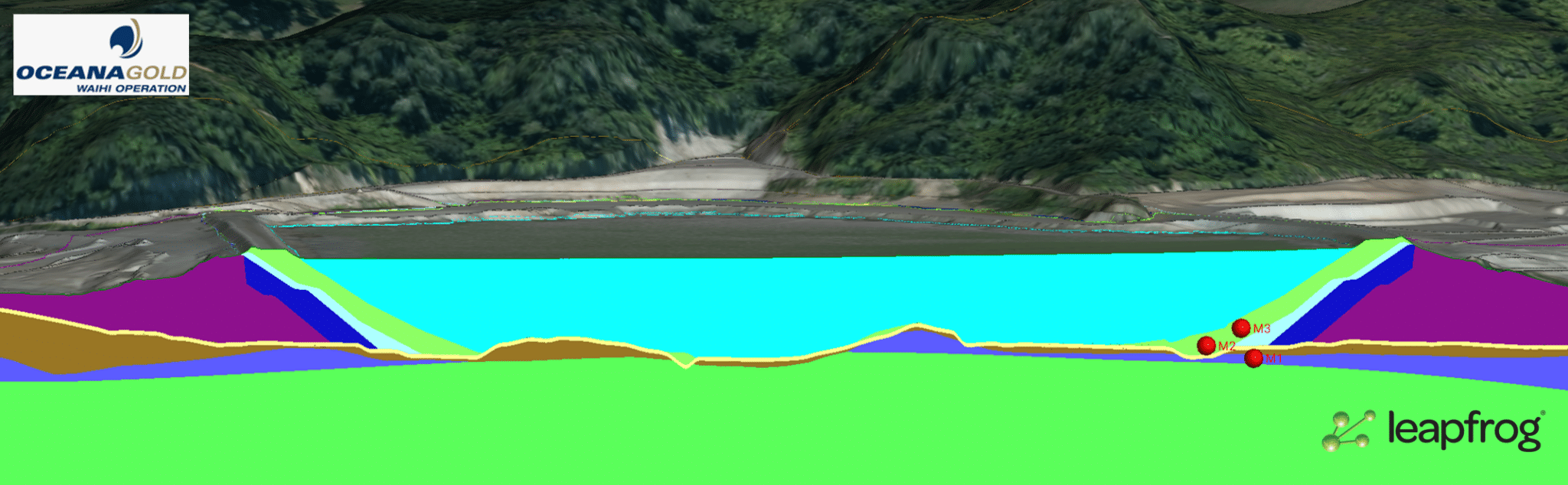

Set against the coastal, green foothills of the Hauraki District, Waihi’s tailings impoundments are carefully engineered earthen structures, made up of several separate layers, designed to the same specifications as a water-retaining structure.

“With dam safety at the heart of OceanaGold’s project, having a fully integrated monitor, model, analysis workflow, with data versioning and auditing metadata, enables transparency at every stage of our project lifecycle,” said Alipate.

Seequent and Bentley’s cloud-based, collaborative workflow integrates data with Leapfrog 3D modelling and GeoStudio analysis, to provide real-time monitoring.

”For our Waihi operation, this streamlined workflow is a technological ‘leap’ bringing real-time connectivity of the structure and inner mechanics of our TSF, with the added ability to conduct workflows for improved safety,

said Alipate.

Core to the digital solution for TSFs is Seequent Central which serves as the knowledge base for the entire Waihi facility, housing all information succinctly, without duplication or multiple versions.

“Historic and current models for the Engineer of Record (EoR) can be easily and quickly accessed to find key outcomes such as reporting and audits for slope stability or to make comparisons following severe weather or seismic events,” said Alipate.

“If an auditor or regulator requires a certain document, at a particular point in time it can be accessed very quickly without having to chase our data or fish through files,” he said.

The 3D digital twin brings the ability to ‘walk through’ and assess each section of your model. (Image: OceanaGold)

Protecting an industrious local community and a unique environment

Going digital has helped OceanaGold to minimise field time, simplify complexity, identify changes, manage risk, make decisions, collaborate with the Engineer of Record and other stakeholders, and improve day-to-day operations, workflows and efficiencies.

”A big win for us simply comes down to housekeeping. We collaborate more, we're more organised and way more efficient. And most importantly it’s ensuring that we meet standards and uphold our responsibilities and social license to operate in this unique and beautiful part of the world,

said Alipate.

Renowned as a gold town, Waihi also hosts prosperous fruit and dairy industries in a landscape punctuated by pristine rivers, beautiful coastlines and unique flora and fauna all holding significant cultural relevance to local iwi.

“Another positive impact of going digital is more responsive management and governance, to ensure better resilience and ultimately minimise environmental risks or impact to our local communities,” said Alipate.

OceanaGold were finalists in the Subsurface and Modelling category in Bentley’s prestigious 2023 YII Going Digital Awards in Infrastructure. Andre Alipate and the team are recognised for piloting an innovative digital response to better manage their Waihi Tailings Storage Facility in New Zealand.