Seequent’s Leapfrog Geo and Seequent Central have been introduced to Yılmaden Holding’s mining camps in Kazakhstan and Turkey increasing drilling accuracy by 22% and decreasing the time spent on geological modelling by half.

The Project

Yılmaden Holding, a subsidiary of the Yıldırım Group of Companies, is one of the world leaders in the production of high-quality high carbon ferrochrome (HC FeCr) and mining of high quality chromite ore. The 4th biggest player in the global chrome industry, Yılmaden is the only company that produces chrome ore and high-quality HC FeCr in four countries. Yılmaden’s mineral exploration activities in Kazakhstan and in Turkey spread across seven districts and 34 projects and are located on the Central Asian Orogenic Belt (CAOB) and on the western Tethys with a focus on chromium, copper and gold.

In 2019 Seequent’s Leapfrog Geo and Seequent Central were introduced to seven mining camps in Kazakhstan and Turkey to increase the sensitivity in exploration drillings and models. Central provides a repository and model management for all Leapfrog Geo models, with upper management able to connect, confer and analyse the most up to date models, enabling collaboration on time critical decisions.

”In exploration studies, it has been determined that using Seequent solutions has increased the accuracy rate of drillings by 22% while the time spent creating geological models has decreased by half. In addition, the ease of use of the software has made our work more efficient in terms of the ability for the entire team to work together and for managers to follow the mineral exploration and resource development programmes. This has consequently had a positive financial impact on Yılmaden’s annual drilling budget of between USD 500,000 and USD 1 Million.

Özgür Sapancı, Exploration Manager, Yılmaden

Situation

The CAOB, like other world major accretionary orogens is a complex collage of ancient microcontinents and arc terranes, accretionary wedges; fragments of oceanic volcanic islands (seamounts) and possibly, basaltic plateaus, oceanic crust (ophiolites) and successions of passive continental margins.

Whilst the mineral exploration teams in the seven different regional camps focused on their work locally, they had problems in communicating the progress of the projects and drilling targeting with local administrators and headquarter managers.

Özgür Sapancı comments, “We were experiencing difficulties not only in modelling but in actively sharing the modelling and drilling updates. It was not physically possible for the teams to develop ideas together through collaboration and for the managers to visit and follow the constantly updated drilling programs. All of these problems were reducing the success rate of the drilling.”

While the drilling programs were carried out, the ongoing modelling studies took time, and the mutual examination of the drawn sections between the project team and the headquarters caused delays between planning and implementation. This often led to expensive drilling programs being carried out purely on the initiative of the local field geologists.

Solution

In May 2019 with the aim of creating a 3D collaborative environment among the mining camps in Turkey and in Kazakhstan, Leapfrog Geo and Seequent Central began to be introduced.

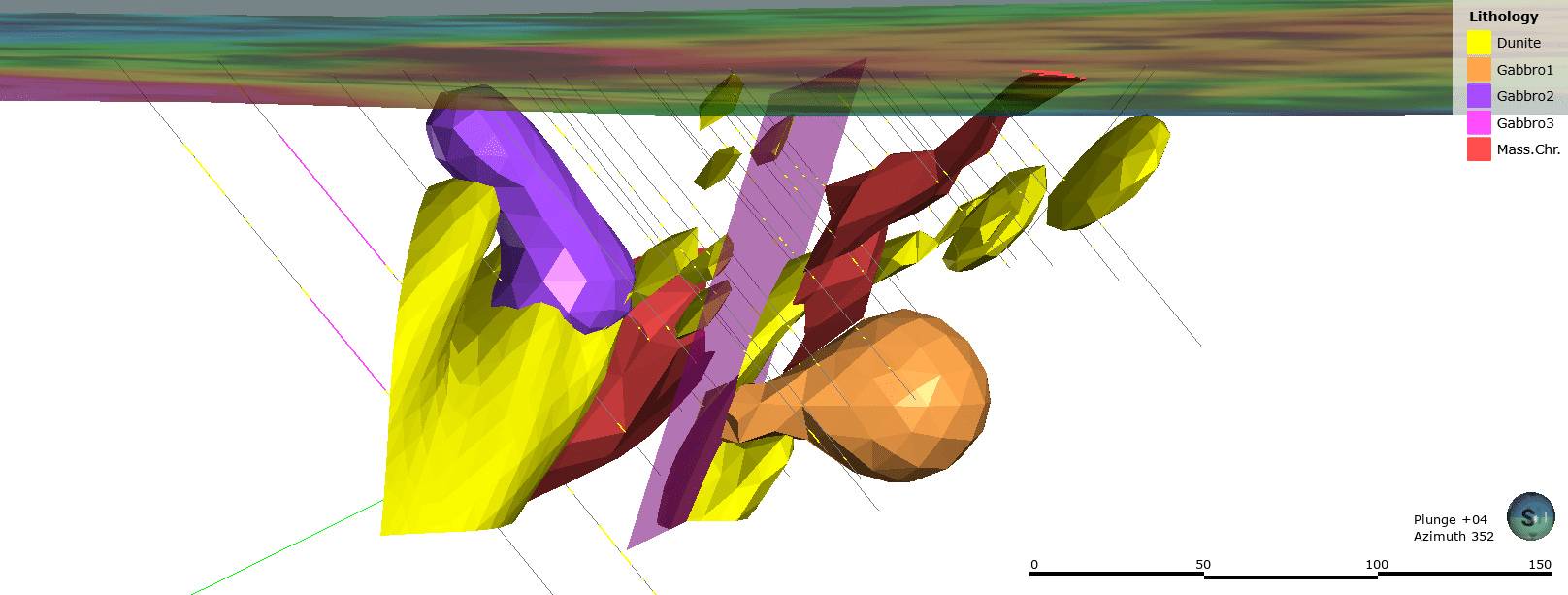

Özgür Sapancı, comments, “One of the biggest challenges faced by drilling in the exploration of podiform chromite deposits is the difficulty of determining the continuity because the ore is subjected to deformation and cut by discontinuities during the tectonic movements. In this context, ore horizons, which we were able to model faster and create dynamically with Leapfrog Geo, were then able to be shared with managers through Central, allowing us to carry out drilling programs collaboratively.”

Figure - 1 Geological model built for a chromite deposit in Leapfrog.

A key feature of Leapfrog Geo is that models are generated directly from the data, bypassing time-consuming wireframing. Models can be quickly visualised in 3D allowing for teams to rapidly gain visual insights to guide interpretations. As new data is added to the model, the rules and parameters already set are automatically applied, ensuring models are dynamic and always up to date. Models are then managed and shared via Seequent Central, ensuring a single source of truth from a centralised, auditable environment where users can collaborate wherever they are based. From field geologists to head office managers everyone can access and see the latest version of project files and models.

”We have been really impressed with the speed, practicality and precision with which we can model and also the ease of use of the software itself and the ease of collaboration made possible via Central.

Özgür Sapancı, Exploration Manager, Yılmaden

To help the team transition to the new system, Seequent’s Egemen Oğuz provided key technical support. Özgür explains, “The weekly Question and Answer sessions arranged by Egemen helped the team quickly onboard with the collaborative geological modelling workflows. Knowing the existence of a scheduled session gave the team peace-of-mind, each team member had the certainty that no questions were left unanswered.”

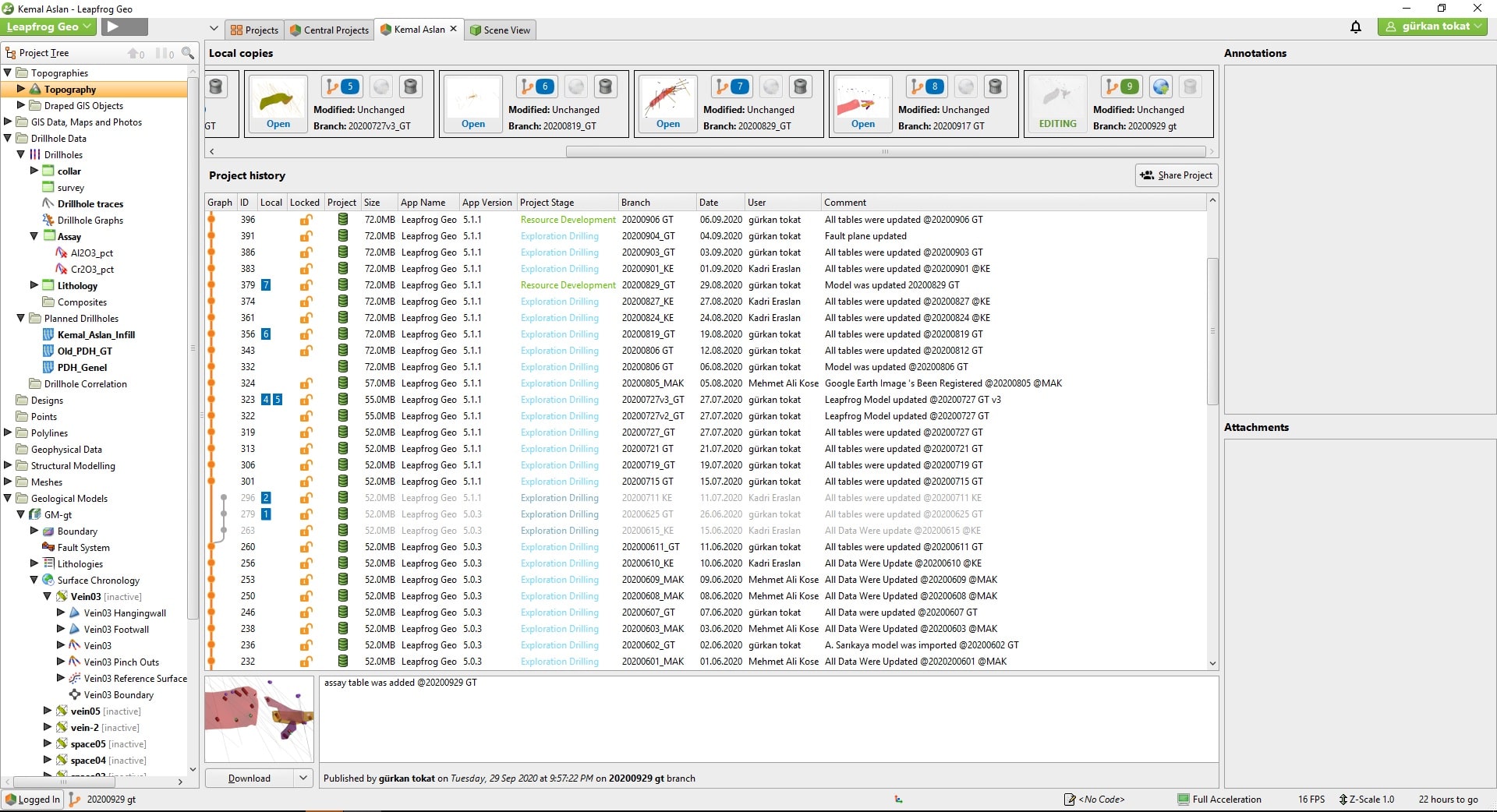

Since implementation, the team have internally focused efforts to ensure that projects are updated weekly and monthly, so that they have ready access to the most up to date information when they need it. Via Central users can easily navigate a complete timeline of a project’s revisions, visually compare model versions and view annotations and conversations to understand how and why decisions were made.

Figure - 2 Leapfrog model versions are stored, tracked and managed via Central.

”Central has allowed Yılmaden’s geological modelling to cross borders, with geologists able to build, update and report on projects centrally from around the globe. And with updates visible and readily accessible from Central, Yılmaden can easily track exploration projects at a corporate level.

Egemen Oguz, Account Manager, Seequent

Outcome

The use of Leapfrog has had a very positive impact on the exploration programme with a 22% increase in drilling accuracy and a 50% reduction in the time allocated to modelling and drilling plans. This precision in the models and the accuracy in the drilling plans has consequently reduced the number of drillings and decreased the cost of exploration, this has positively impacted Yılmaden’s annual drilling budget between USD 500,000 and USD 1 Million.

”Prior to this introduction the Yılmaden Exploration Team believed that geological modelling couldn’t be progressed from the field. With Leapfrog it is now possible for our field geologists to build fast and accurate models on site.

Onur Karakaya, Production and Exploration Director, Yılmaden

Seequent’s solutions have enabled Yılmaden to achieve:

- Modelling speed, and accuracy

- Dynamic model updating

- Rapid and advanced 3D visualisation

- Seamless connectivity and accessibility

- Ease of collaboration between seven exploration sites and management teams

Concludes Özgür, “Leapfrog Geo and Central allows Yılmaden’s teams to analyse, monitor and manage all exploration data in one place. In a similarly beneficial way to the recent developments amongst the top players in the global mining industry, who have increased value by utilising integrated best-in-breed software technologies, it has proven to be an effective concept over the last 3-5 years in the Turkish mining industry. In this context, we have chosen Seequent to help us solve 3D geological challenges in Yılmaden’s Exploration Department.”

In the future Yılmaden plan to introduce Leapfrog Edge, Seequent’s resource estimation solution, which will enable them to streamline modelling and resource estimation into one workflow. Yılmaden also plan to integrate Seequent’s Oasis montaj and thereby benefit from a more holistic modelling approach through the integration of Leapfrog Geo geological modelling and Oasis montaj’s geophysical modelling.

Seequent’s Executive Vice President, EMEA, Colin Hay comments, “We’re really pleased to share Yılmaden’s fantastic success story of how they are benefiting from using Seequent’s solutions. Early adopters in the industrial minerals sector like Yılmaden are reaping the rewards from innovation. We look forward to continuing our working relationship and helping Yılmaden to achieve even more integration as we continue to expand the Seequent Mining Solution throughout the value chain.”