Major infrastructure projects need an ongoing understanding of ground and ground water conditions to hone engineering decisions. Dynamic 3D ground modelling solution, Leapfrog Works, helped Arup to effectively create a digital model of the geology for London’s proposed Crossrail 2 railway.

The Project

Multidisciplinary professional services firm Arup was contracted by Transport for London (TfL) to develop a 3D ground model in order to identify geological hazards along the route, inform early design decisions and provide the project with an invaluable geotechnical risk management tool.

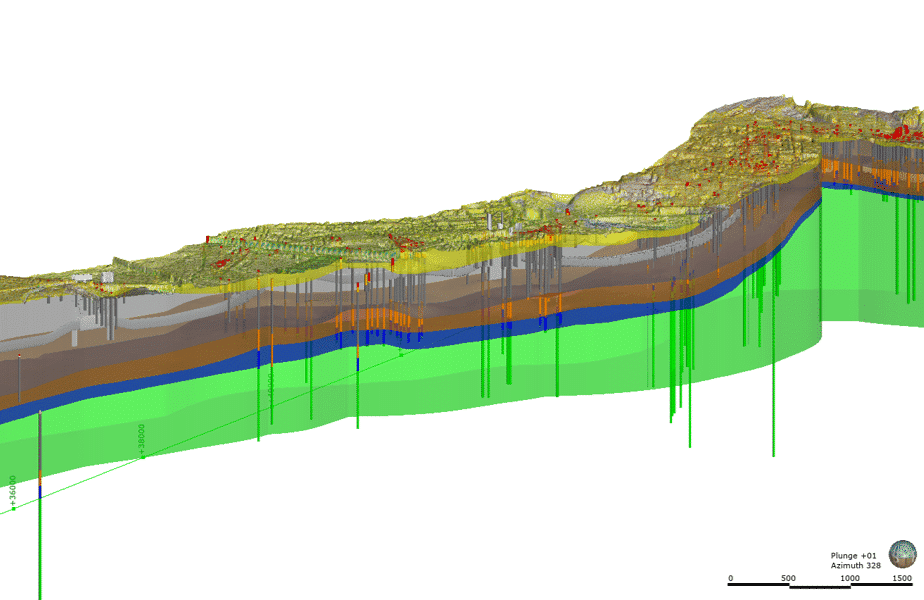

The proposed railway will link the national rail networks in Surrey and Hertfordshire via approximately 30 km of underground tunnel. Leapfrog Works was used to develop this detailed 3D ground model to understand ground and groundwater conditions that would impact on engineering decisions. Avoiding or mitigating the risks that any potential hazards posed was critical to allow for robust and realistic estimates of the project programme and cost.

Leapfrog Works is a dynamic 3D subsurface modelling solution that turns complex data into clear, easy to interpret models. Works helps visualise and understand the geology for communication and honing the decision making of civil engineering projects. Geological models can also be easily combined with engineering designs, BIM workflows and groundwater flow models, further reducing risk and improving decision making.

Stuart Mills, Arup’s Associate Director in Infrastructure Hong Kong comments, “Leapfrog Works enabled us to visualise the geological base model and other formats of geological data in 3D, undertake refinements to the model and effectively communicate uncertainty and spatial variation in geology. We were able to feed the geological surfaces into our data driven approach to design decisions, which supports our drive towards digital automation of engineering design. Being able to have this data driven workflow in place so early on the project has been really valuable and was appreciated by us and Transport for London.”

Situation

The new railway will improve access to and from London across the wider south east region of the UK and significantly reduce congestion on existing Tube and National Rail services. Crossrail 2 will support 200,000 jobs, spur the development of 200,000 new homes across the region and increase London’s rail capacity by 10%, complementing other major national transport projects, such as High Speed 2.

Crossrail 2 is at the very early stages of planning. TfL expect to seek permission from the UK Government to build Crossrail 2 in order to start construction later in the 2020s, with the new line opening to the public in the 2030s.

Ground and groundwater conditions influence engineering considerations such as alignment design, ground improvement options, requirements for groundwater management, and selection of construction method. These considerations, in turn, can significantly influence the constructability of proposed structures, project costs, and programme.

Major infrastructure projects gain momentum as the project gains traction politically and public funding is unlocked to progress design and procure surveys. However, at the outset of the project, before new ground investigations are undertaken, key decisions need to be made based on reliable information, including an understanding of the ground and its impact on the overall project.

The need for a detailed 3D geological model was therefore identified early in the feasibility design stage. It was important to ensure that the nature and potential distribution of ground-related hazards were understood from the outset using the available geological information. Early stage avoidance or mitigation of the risks that these hazards pose was critical to allow for robust and realistic estimates of the project programme and cost to be developed.

Response

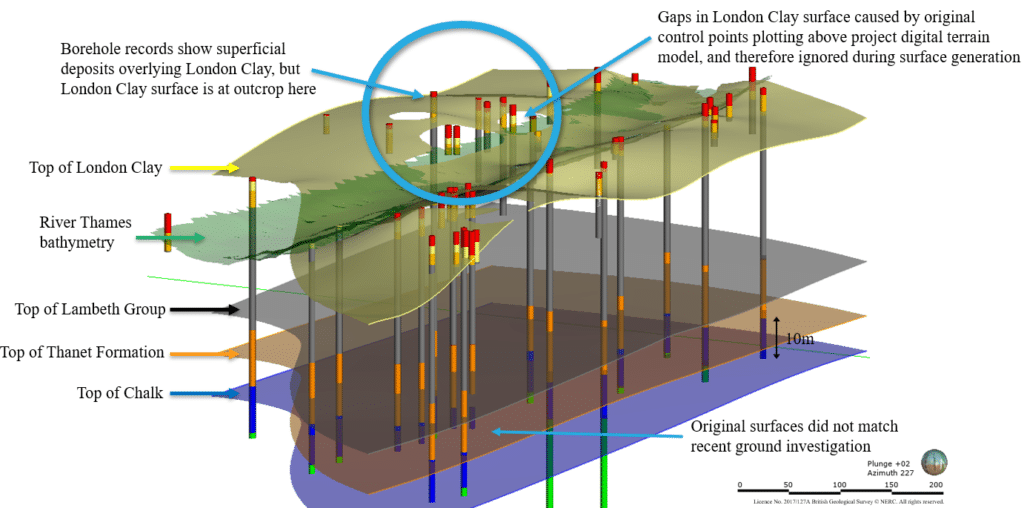

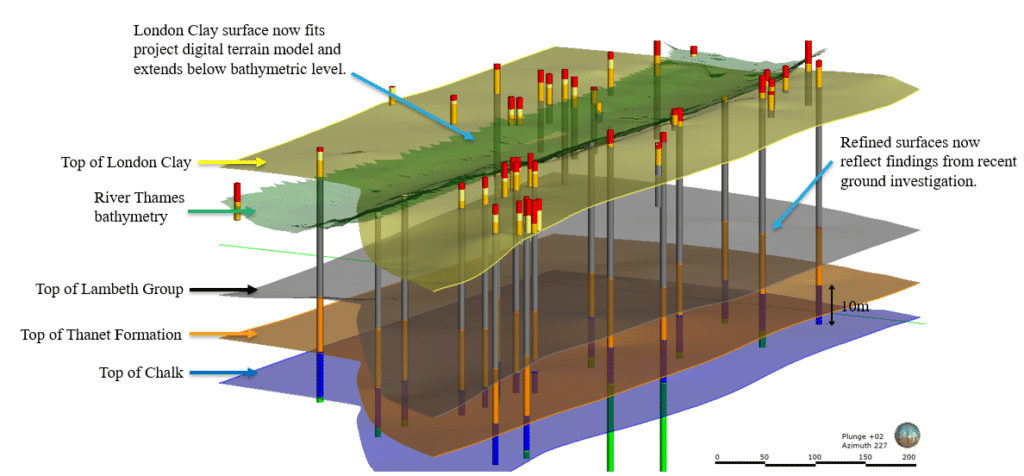

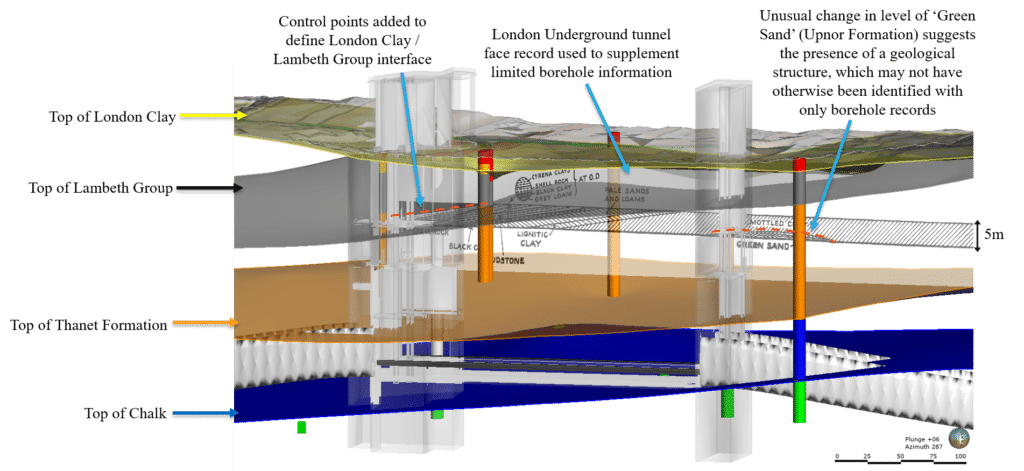

Work on developing the Project Stratigraphic Model for Crossrail 2 was initiated in early 2018. An extract from The British Geological Survey’s (BGS) 1:50,000 scale 3D model of the London Basin was adopted as the baseline Stratigraphic Model. Leapfrog Works was used to integrate additional information available in the form of additional boreholes, higher-resolution digital terrain models, historical and recent publications on the construction of the London Underground and other major infrastructure projects, such as Thames Water Ring Main, Crossrail, Thames Tideway and others.

Arup’s Senior Engineering Geologist, Charlene Ting explains, “We used Leapfrog Works to refine the baseline Project Stratigraphic Model, by undertaking site-specific reviews of the model at priority locations, so that the model reflected the local geology rather than the regional geology, and better suited project requirements. Developing a ground model is an iterative process so it’s essential that we’re able to refresh it with new information. Works’ dynamic updating feature allowed us to easily do this.” These priority locations were selected based on a combination of factors, including locations of proposed stations and areas where the BGS modelled geological surfaces significantly varied from the additional borehole records. Original control points were modified to better match the higher-resolution topographic data.

Charlene explains, “As an example of how we were able to use Leapfrog Works, we initially used a 2D cross-section to illustrate the ground conditions at one location but found it difficult to communicate the lateral and vertical variability in the stratigraphy, which were locally complex due to the presence of potential faulting or folding. Using Leapfrog Works we were able to demonstrate how far apart the boreholes presented on the 2D section were actually offset from the proposed structure. We were also able to vertically georeference cross-sections from existing publications to supplement the sparse borehole data and visualise the complex ground conditions at that location. Additional control points were created to ‘digitise’ the published sections. This improved our understanding of the ground, successfully highlighted data gaps and uncertainty and informed the wider team’s decisions regarding the vertical alignment of the proposed tunnels, station design and ground improvement requirements.”

Used in combination with other digital tools, Leapfrog Works is designed to work effectively with existing workflows. Works’ CAD and GIS friendly ability allowed the team to interoperate effectively with ArcGIS and tools such as Bentley gINT, InRoads, MicroStation and Autodesk AutoCAD.

Outcome

“Using Leapfrog Works helped us identify locations of higher geological uncertainty more efficiently, and we sought out multiple sources of geological information available for the area to examine in closer detail. Being able to highlight these areas of uncertainty helped us to target any further ground investigation and maximise efficiency in planning future works.”

Charlene Ting, Senior Engineering Geologist, Arup

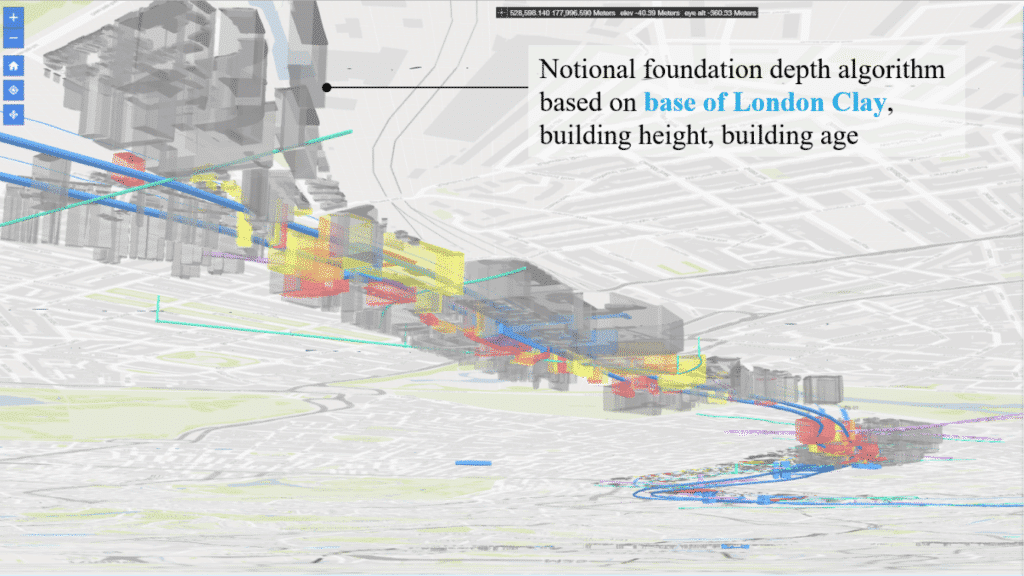

The refined 3D geological surfaces were subsequently fed into a data-driven approach to inform design decisions, shortcutting iterations of the development of 2D sections along new alignments and at key civil structures such as shafts, portals and caverns, and informing dynamic obstruction clash risk assessments.

Charlene Ting explains, “If the alignment was changed we were able to just refresh the model and see what it looked like with the new alignment. Other tools were available to us at the time but they required a high level of geostatistical expertise and were time consuming. Leapfrog Works gave us a quick and easy solution with their fast radial basis functions and helped us with being able to go through this iterative refinement process.”

A comparison of the results of using the different interpolation methods was carried out and there was generally a good agreement. Further model validation is planned once more data is available.

Visual communication aid

Leapfrog’s collaboration tools, View and Viewer, were used to easily share the modelling with TfL as well as the wider, multidisciplinary project team, including geotechnical and civil engineers. Everyone was able to readily visualise in 3D and interact with the model, turning and slicing it for different perspectives which proved very effective in collaboration and communication.

Arup’s Geotechnical Lead for Crossrail 2, Ben Gilson, comments, “Being able to readily share the 3D model led to a noticeable uptake in engagement from internal Arup teams, subconsultants and TfL who noted that more people were opening up the 3D model because it was displayed in a more interesting and interactive way. This was a win for us in terms of sharing the data and getting the wider team to buy in to the geology and ground conditions. We were also able to add our caveat assumptions and limitations to the model so everyone was able to review this commentary and appreciate where there was uncertainty. We were able to use the data in a number of ways, pulling data straight into other packages from the 3D model and we could also extract 3D volumes out of different spoil types and determine best ways to use them.”

Data-driven design and assessment enable a link to be developed between alignment design, evolving understanding of ground conditions, and building obstruction data and analysis. High-level planning is underway for a ground movement assessment workflow, driven by data from the Asset Portal and Project Stratigraphic Model. The incorporation of geotechnical parameters into the Project Stratigraphic Model will enable data-driven workflows for the design of structures such as retaining walls. It is anticipated that the Project Stratigraphic Model will be updated during the construction stage and it will prove to be an invaluable construction planning and risk reduction tool in the long term. It effectively creates a geotechnical digital model as an integral part of the digital assets of the project.

“We want to spend less time processing the data and more time understanding the data. It’s a no brainer. The work speaks for itself. The quality and level of detail we are getting at this early stage of the project really is fantastic and very useful. It really is a step change to what I have seen previously.”

Principal Geotechnical Engineer for Crossrail 2, Mike Black.

Stuart Mills concludes, “Leapfrog Works has been identified as a key ground modelling tool that we have included in our toolkit to approach ground modelling. We have seen the benefits of iterative modelling, clear 3D visualisation and ensuing data-driven design that adopting Leapfrog has provided on several projects. We look to continue to adopt Leapfrog Works on projects going forward.”

Seequent’s Civil Segment Director, Pat McLarin, comments, “Transport infrastructure projects like Crossrail 2 are large and complex and require a thorough and evolving understanding of the sub surface conditions, while effectively sharing and communicating findings with a variety of stakeholders. Seequent’s Leapfrog Works addresses these challenges while allowing users to easily combine geological models with engineering designs for in-depth insight and better decision making.”