The Project

Edna May Gold Mine operated by leading, growth focused Australian gold miner, Evolution Mining, is located 350 km west of Perth and 2 km from the township of Westonia, Western Australia. Gold mining has occurred as underground and open-pit operations over three distinct periods since it was first discovered in 1911. The current open-pit mining operation recommenced in 2009, with concurrent underground mining starting in 2016. To date over 1 Moz has been mined from Edna May.

The Edna May deposit is a complex orebody that showcases the associated geological risks which impacts mining performance. Geological risks involve the orientation and continuity of mineralisation, together with the structural architecture of the deposit. Past periods of poor production performances demonstrate the inherent risks in failing to continuously develop the geological understanding of an orebody.

In 2014 Evolution first introduced Leapfrog Geo to generate a geological model for the 2014 Mineral Resource estimation. This was a major change to the geological modelling process compared to previous years that utilised traditional explicit (polygonal) techniques. Since early 2016 Evolution has further implemented the use of Leapfrog Geo to enable the dynamic and rapid updating of the Grade Control (GC) block model.

Says Hans Andersen, Group Resource Geologist, Evolution Mining, “Using Leapfrog Geo we are able to model a highly complex geology, giving improved representation of the various geological units. For the past 18 months Leapfrog Geo has also supplemented our grade control process enabling the dynamic updating of our GC block model. This has freed up significant modelling time and allows staff to concentrate on other high value geological activities.”

Situation

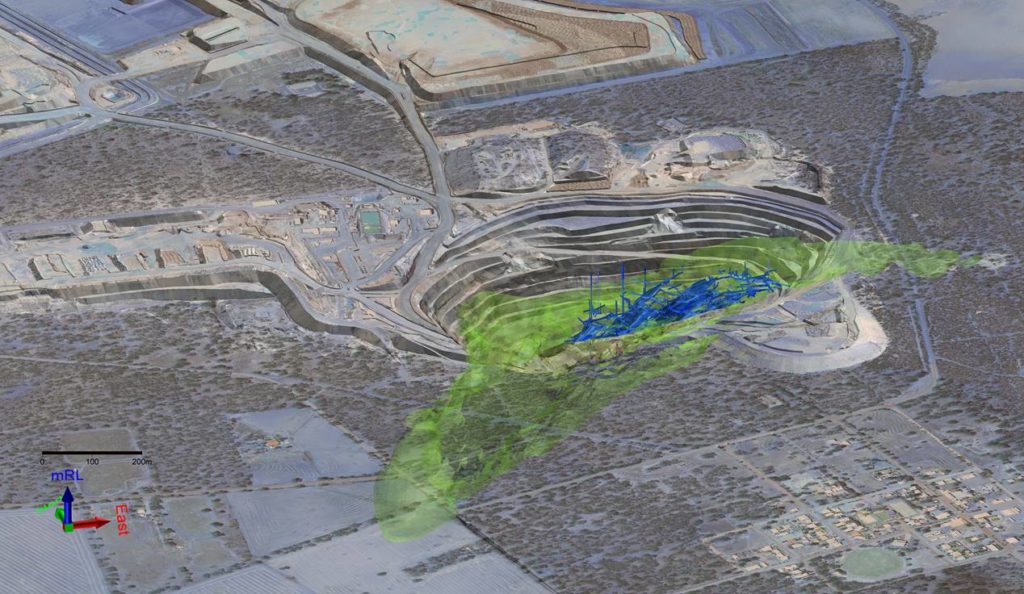

The Edna May deposit is situated within the Westonia Greenstone Belt, in the Southern Cross Province of Western Australia’s Archaean Yilgarn Craton. Locally the Westonia Greenstone Belt sequence strikes west-northwest (WNW) and dips north-northeast (NNE) at approximately 50-60 degrees. The Westonia Greenstone Belt also hosts the adjacent Greenfinch and Golden Point deposits along strike of the main Edna May deposit (Figure 1).

The Edna May deposit, defined by the mineralised Edna May Gneiss (EMG) host sequence has a currently defined strike length of 1 km, width of 140 m and depth extent of 700 m. Gold mineralisation is structurally controlled and is primarily hosted exclusively within the Edna May Gneiss associated with quartz veining. Two types of veins are identified within the Edna May deposit being the stacked arcuate veins representing the historic gold production; and the second type being thin sheeted quartz veins in either a ladder or stockwork association.

Failing to continuously develop the geological understanding of the orebody had proved in the past to be detrimental to production performance. By introducing a new dynamic system Evolution could make ready use of the latest grade control information and, by replicating the complexity of the geological model used for the 2015 Mineral Resource estimation, they would also be able to significantly improve accuracy.

Response

Moving to the new dynamic system took three days to implement in cooperation with site personnel, including modifications to the site geological database.

The goal was to replicate the Leapfrog Geo generated geological model initially developed for the 2015 Mineral Resource estimation. This was a major change to the geological modelling process at Edna May compared to previous years.

“For the past 18 months Leapfrog Geo has also supplemented our grade control process enabling the dynamic updating of our GC block model. This has freed up significant modelling time and allows staff to concentrate on other high value geological activities.”

Hans Andersen, Group Resource Geologist, Evolution Mining

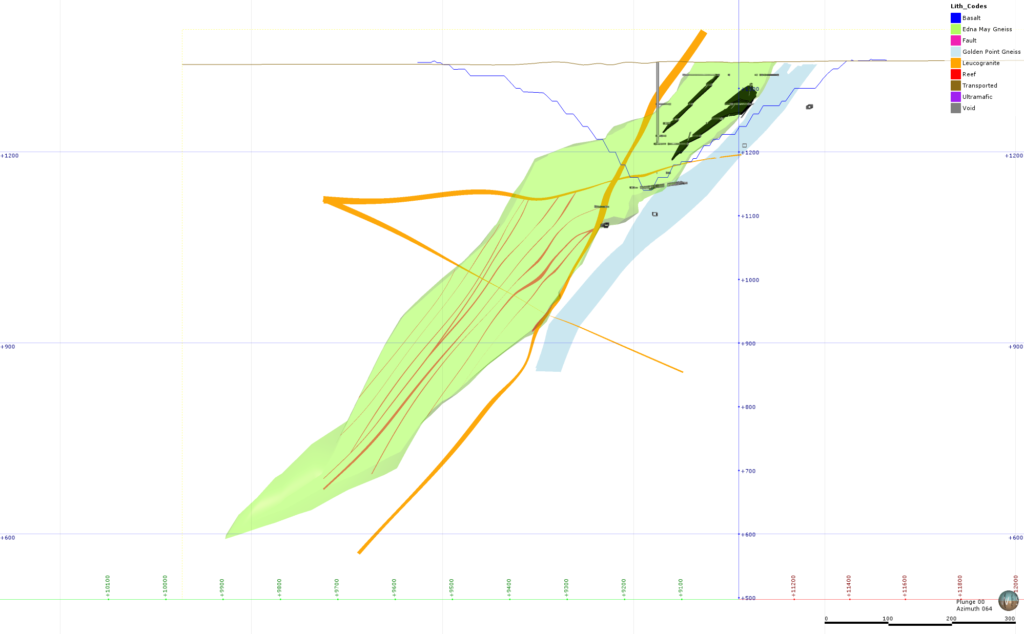

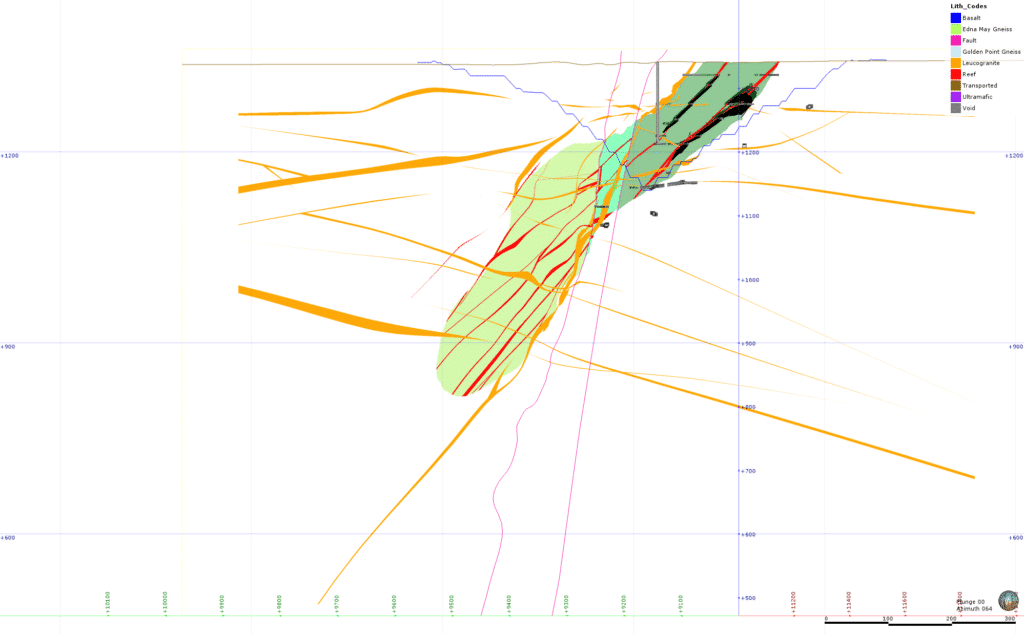

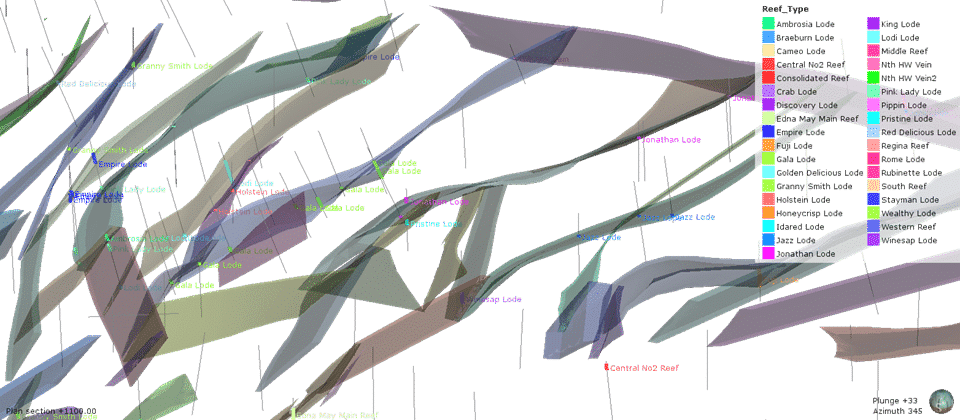

As you can see when comparing Figure 2 and 3, (before and after Leapfrog Geo’s introduction), the geometry and number of mineralised domains and geological rock units able to be modelled using Leapfrog Geo represented a significant step change from previous estimates and methodology. The number of modelled ‘barren’ dykes went from only 4 to over 30, providing a significant improvement in the operations management of dilution and waste material during mining. Additionally, the complexity of the arcuate reefs could be better modelled, with the number of quartz reefs being modelled going from 11 to over 30.

As Figure 3 shows, the Edna May Gneiss (shades of green) is now faulted into three domains, and removes the lower extension of the Golden Point Gneiss (pale blue) from the pre-2014 modelling, this also shows increased complexity of the reefs (red) with numerous additional intrusive dykes (yellow) now being modelled.

“Leapfrog Geo allows us to model the geology accurately, honouring the drillhole intersections through a combination of using the vein and intrusive 3D surfacing tools.”

Mathew Van Rensburg, Edna May’s Project Geologist

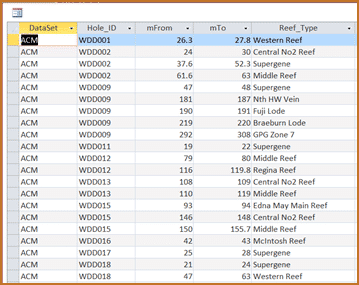

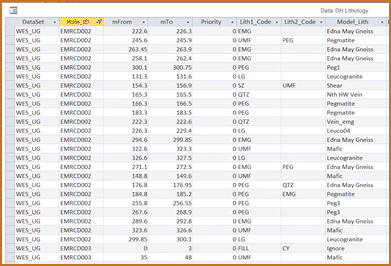

A key driver of the process was the alteration of the database to directly code the geology in a consistent manner for the geology logging and assay information; thus driving the automatic updating of the geological model when refreshed with the latest grade control information. The system uses validated codes from the database in updating the Leapfrog Geo geological model.

Commented Mathew Van Rensburg, Edna May’s Project Geologist, “Leapfrog Geo allows us to model the geology accurately, honouring the drillhole intersections through a combination of using the vein and intrusive 3D surfacing tools. These 3D solids are then exported to Surpac and used to control and code the Surpac block model. The Leapfrog Geo modelling and Surpac estimation are driven by the single source of coded information from the database. The power of the system is the integration of the database, Leapfrog Geo and Surpac to quickly and consistently update and generate the grade control block model. Using the database as the single source of truth allows for quick review and an auditable and secure process.”

Outcome

For the mine site a key benefit gained from using Leapfrog Geo was being able to integrate the two separate open-pit and underground geological models into one consistent geological model, making modelling much faster and more efficient. With this new system in place it is now possible to perform dynamic and rapid updating of the GC block model. This has significantly reduced the time taken to update the GC block model with complex geology and has improved ore selection and reconciliation performance.

Commented Hans Andersen, “Drillhole data is updated, reviewed and validated into the database on a routine basis every couple of days with the results reviewed in Leapfrog Geo for consistency and coherence with the geological interpretation. The updated surfaces are then exported to Surpac to update the GC block model through an automated scripting process once each digblock drill program is received. This may occur daily to once a week, depending on the volume of grade control drilling that occurs.”

By having a representative geological model, geologists can identify what features to expect before logging commences and are able to log RC chips more effectively.

Continues Hans, “Since the final implementation of the new processes we have improved geological understanding and consequently improved reconciliation practices and performance.”

Cross team use

The five strong team all utilise Leapfrog Geo to update the GC block model with two main users overseeing the process. The model is stored on the site server and all staff have access to the latest version and model outputs. Leapfrog Geo’s user friendly and intuitive interface means that new users are also able to easily update complex geology after each grade control drilling campaign, saving considerable time and streamlining the workflow. Following the successful implementation of the new system Evolution plans to introduce a similar workflow to other mines.

Concludes Leapfrog’s Regional Director, APAC, Karl Howley, “The introduction of Leapfrog Geo into the new grade control process at Edna May has had a significant impact. This is a direct result of the improved accuracy gained using Leapfrog’s vein modelling workflow. The new process also makes ready use of the latest information and as data processing is now automised it saves considerable time, a third of the time when compared to previous methods. Accurate and timely geological modelling provides an opportunity to increase production efficiencies and reduce costs. We look forward to continuing to work with Evolution Mining to help further improve their geological modelling capability.”