This article was first published in the 2023 March edition of Infrastructure Magazine Australia.

What are the leading causes of delays, disputes, and major claims in infrastructure projects?

A recent CRUX Insight Report identified ‘unforeseen physical conditions’ in the top 10, alongside more commonly recognised challenges such as, ‘changes in scope’ and ‘design-related issues.’

Pat Mclarin, Civil Director, at Seequent, the Bentley Subsurface Company, said managing ground risk is a live industry issue. Mr. Mclarin has over 20 years experience as a product manager in the research and development of geospatial hardware and software, with a focus on subsurface solutions during his last six years at Seequent.

“Unearthing the unexpected can completely derail a project, with changes coming at significant cost,” Mr. McLarin said.

As teams react to source new equipment, bring in fresh expertise or train team members, project progress can often stall, or halt completely.

“Rather than accepting the status quo, the latest in digital innovation can help bring a better understanding of the geological complexities at every stage of your project.”

Shortcuts cost in the long run

A deeper understanding of the subsurface is crucial for infrastructure design and construction. “Geotechnical engineers responsible for this essential early- stage phase are under the pump to ensure it’s done accurately, as well as efficiently,” Mr McLarin said. But when project owners look for ways to cut costs, speed up production, or maximise construction dollars, it can be quickly compromised.

The CRUX study brings this to light. Globally, the trend is clear – taking ground investigation shortcuts can lead to a multitude of challenges down the track.

“The squeeze on geotechnical teams shows no sign of letting up and so the industry must learn to adapt,” Mr McLarin said.

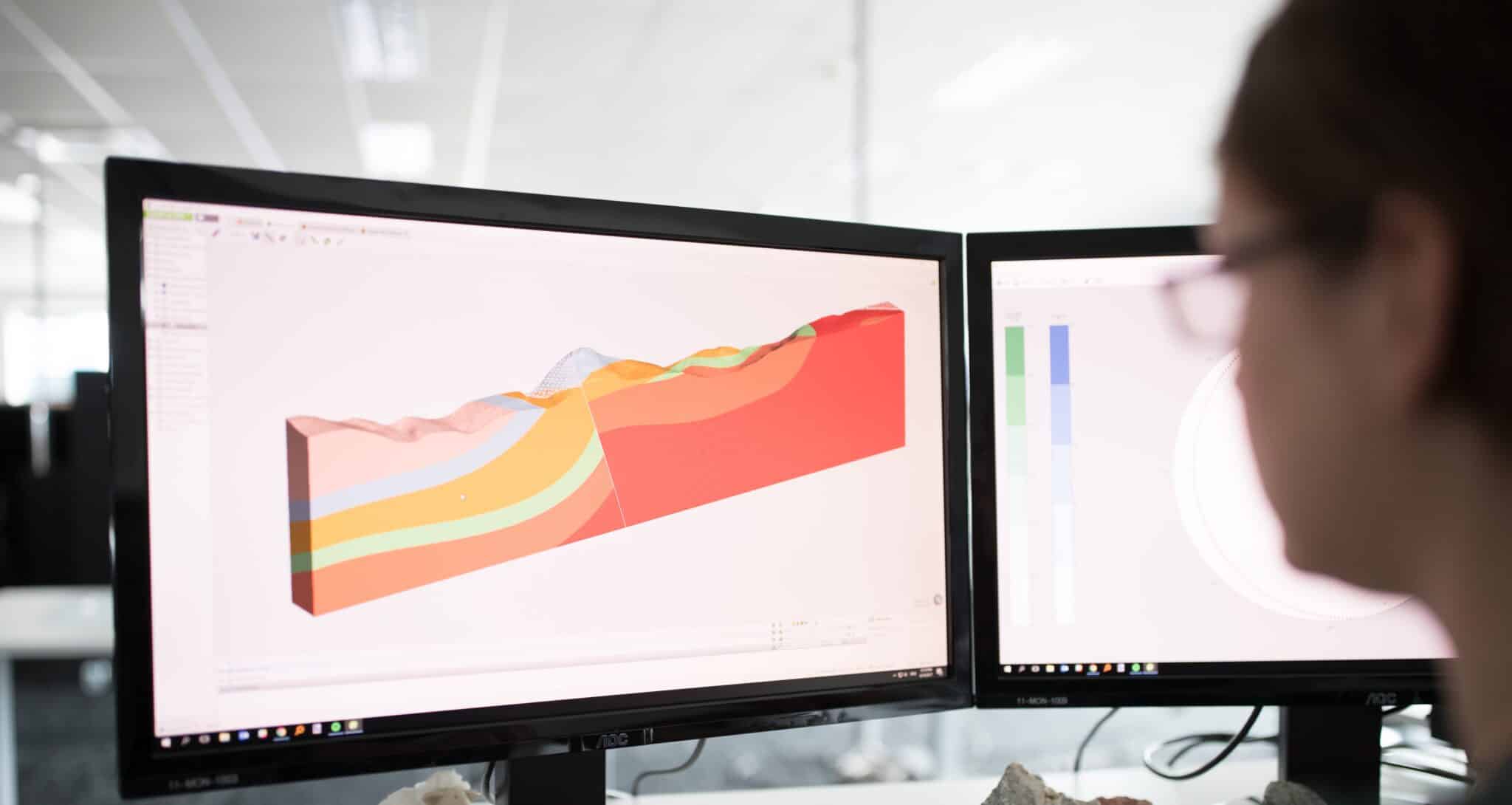

“Adapting means meeting the demand for speed while still delivering accurate, usable insights. Digital innovations that quickly and easily collate geotechnical data into 3D models can bring deeper insights, deliver more value and support better decisions.”

Making a difference on Melbourne tunnel project

Mr McLarin leads Seequent’s strategy for civil infrastructure and participates in open standard development to raise the profile of the geotechnical disciplines in BIM and digital twins. Digital modelling, digital twins and BIM technologies were identified in the CRUX Insight Report as helping project teams manage complexity and work smarter. The West Gate Tunnel project in Melbourne is one of a multitude of complex infrastructure projects currently underway worldwide where Seequent software has made a difference.

The project involved an exhaustive investigation of geological risk, led by geotechnical services firm WSP Golder. It used the 3D implicit modelling solution offered by Leapfrog Works to help assess geological risk and communicate that to a variety of stakeholders.“ Our subsurface software helps you easily combine all geotechnical information into auditable workflows for teams, contractors and joint ventures,” Mr McLarin said.

“This means everyone has the latest insights and can collaborate on a shared up-to-the-minute understanding of the subsurface, to make faster decisions and quickly progress a project.

“As we build back better, digital transformation will become the norm for ground engineering on infrastructure projects, allowing faster project delivery, with more certainty and to achieve a better outcome.”