The application of new digital workflows is one of the areas explored in Seequent’s new insights paper, Beyond the Hype: how technology can drive mining operations’ performance. The paper reveals the challenges and benefits associated with integrating digital workflows into mining operations.

The insights paper brings together thought-provoking and insightful contributions from leading industry experts from AngloGold Ashanti, Hecla Mining, IntelliSense.io, RockMass Technologies and Seequent. It examines technology’s potential to make mining operations safer, smarter and more cost effective, with some of the most notable sections focusing on the role of digital workflows in optimising mining operations.

Integrating new digital workflows

New innovative technology used in mining is generating more detailed data than ever before. LiDAR scans of underground excavations create 3D, high resolution, georeferenced images of rockface. This information can be utilised to provide better grade control, cut costs, and increase productivity. However, mining organisations can extract even more value from this data if they manage it with the help of digital workflows.

RockMass Technologies’ RockMass Eon LiDAR scanner used by geologists and geotechnical engineers to improve accuracy, efficiency, and safety of mapping underground.

A major challenge for the sector is the integration of new digital workflows across an organisation. Currently, companies are having to purchase technology from several vendors. Often, the different technologies are not compatible with each other, creating silos and disjointed time-consuming workflows.

The challenge is compounded by a lack of standardisation across the industry, making it difficult for mining companies to find and adopt a common digital workflow solution. Matt Blattman, Director of Technical Services, Hecla Mining, explains, “We’d like to standardise, but within our own company, with four different mines, four different types of deposits and four different mining methods, it’s hard to find something that fits every situation.”

Encouraging teams to use a new workflow can be a challenge too. There is frequently a degree of resistance to change, and people will look for a reason to revert to their old ways of working. Dr. Grant Kopec, VP of Global Field Operations for Intellisense.io, comments, “One of the things that kicks people out of a new workflow and back into the old one is a data quality or a data outage issue where they say, see it’s not working or it’s inaccurate.”

Mining executives need to ensure a high degree of personal interaction and comprehensive support to teams to ensure the new systems are smoothly integrated into the operations and used consistently.

Bringing together data, services and applications in real time.

In many mining operations, the geologists are stuck with the workflows dictated by the systems they use. According to our recently published Geoprofessionals Data Management Report, geoprofessionals in mining said they spend 27% of their time on data, and while this is a marked improvement from previous years, adoption of digital workflows will lead to better operational performance.

Alex Boucher, Technical Solutions Director, Seequent, explains, “Within an open cloud-based environment of solutions connected through seamless integrations, mining companies will be able to bring together data, services and applications in real time.” Adoption of these digital workflows will put the right information, from raw data capture to mine modelling, into the right hands at the right time.

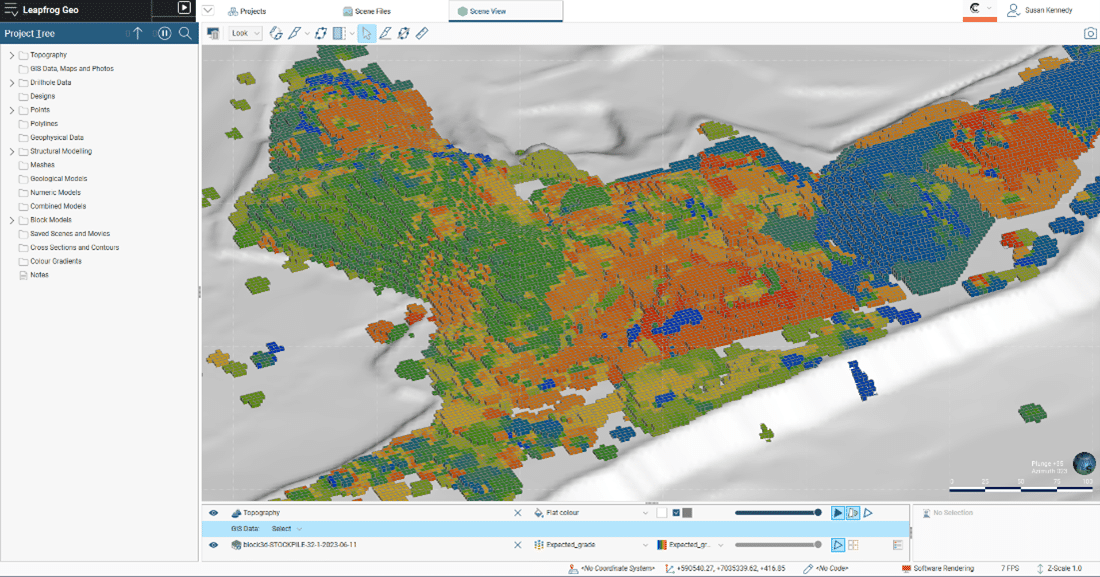

Industry-first 3D block models of real time ROM pad stockpiles generated by the IntelliSense.io Stockpile & Inventory Optimization Application, integrated into Leapfrog and Seequent’s ecosystem to give a full high-fidelity view of material inventories and variability across the mine.

Towards digital transformation

In our new insights paper, industry thought leaders are advocating the integration of digital workflows as an essential step to improving performance. Mining needs to use new technology to work smarter and optimise operations.

High-performing operations are enabled through partnerships – like-minded innovators working together to solve real-world mining challenges,” says Pieter Neethling, Segment Director, Mining Operations at Seequent.