Lieberman Engineering, Residential Development, Hamburg Germany

The Project

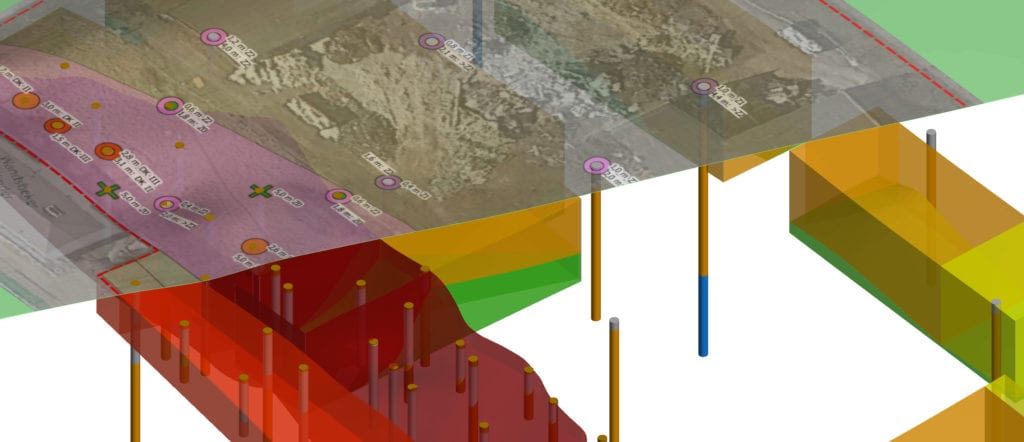

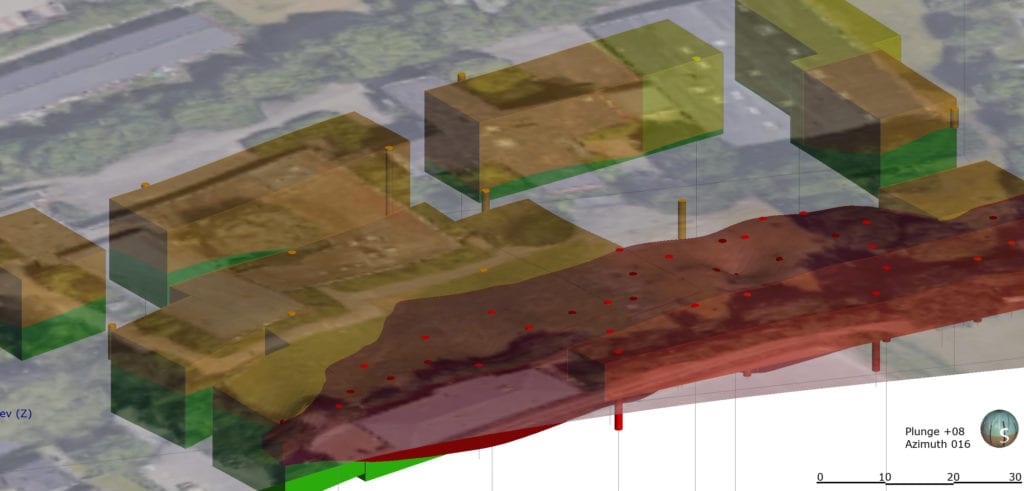

Construction and environmental experts, the Lieberman Engineering Company, were contracted by housing construction cooperative, the SAGA Group, to produce a geotechnical report and landfill disposal concept for planned residential buildings in Hamburg, Germany. Lieberman used Seequent’s dynamic subsurface modelling solution, Leapfrog Works, to produce a 3D model to communicate and visualise the contaminated land associated with the site.

Lieberman are also using the project to advance their pursuit of progressive digitisation in preparation for Industry 4.0, a future high-tech vision of the German government. The intelligent 3D model-based process, Building Information Modelling (BIM), will become standardised over the construction industry and Lieberman recognise the benefit of early upskilling in geotechnical engineering and geological exploration 3D modelling. Leapfrog’s easy to understand functionality and user-friendly interface allow users to quickly upskill and take advantage of operating in a 3D environment.

Tobias Querfurth, M.Sc., Geological Engineer, Lieberman Engineering, comments “Leapfrog Works is one of our central software products for successful digitalisation of our workflows. Leapfrog delivers a realistic representation of geological data and supports geotechnical workflows without the need for professional CAD-based modelling skills. Its clear structure helps us achieve our goals of increased efficiency in data visualisation which in turn enables better, transparent communication with all stakeholders. ”

Situation

The property is currently owned by the city of Hamburg and was formerly a school with an adjacent landfill, which has been out of service for several years. The project will enable useful reutilisation of the land, with demolition of the existing buildings and redevelopment into nine residential buildings of approximately 211 flats, creating much needed living space in the growing city.

SAGA contracted Lieberman to carry out site and environmental investigation, to assess the geological subsoil and examine the landfill. The two project-specific deliverables were:

- Preparation of a geotechnical report with recommendations for safe foundations (settlement and ground seepage calculations), drainage systems, excavation pit construction etc.

- Exploration of the exact dimensions of an old landfill and the development disposal concept for the different landfill bodies and other environmental pollutants.

Most BIM-capable products that are used for geological and geotechnical applications require extensive CAD knowledge. Due to this, the effort required for 3D modelling can quickly outweigh the visualisation benefits when working on small or mid-size projects such as this. Seequent’s 3D geological modelling software, Leapfrog Works, offered Lieberman the opportunity for straightforward digitisation of data in accordance with the requirements of the BIM working method.

“Due to Leapfrog’s intuitive functionality, geologists or geotechnical engineers are able to work on models themselves, rather than employing a CAD specialist as we’ve had to with other modelling solutions. This means we can use Leapfrog for even small projects and can integrate it into a consistent digitised workflow that can become standard for all of our geotechnical and geological projects,” explains Tobias Querfurth.

Leapfrog delivers a realistic representation of geological data and supports geotechnical workflows without the need for professional CAD based modelling skills. Its clear structure helps us achieve our goals of increased efficiency in data visualisation which in turn enables better, transparent communication with all stakeholders.

Tobias Querfurth, M.Sc., Geological Engineer,

Lieberman Engineering

“Leapfrog is very easy to use and I haven’t needed any specific training. Previously I would have relied on a CAD specialist for modelling, now I can do this myself and directly apply my geological understanding to the model. The functionality is very clear and when and if needed, Leapfrog support is quite exceptional.”

Response

Lieberman had a number of key requirements for their Leapfrog use, these included:

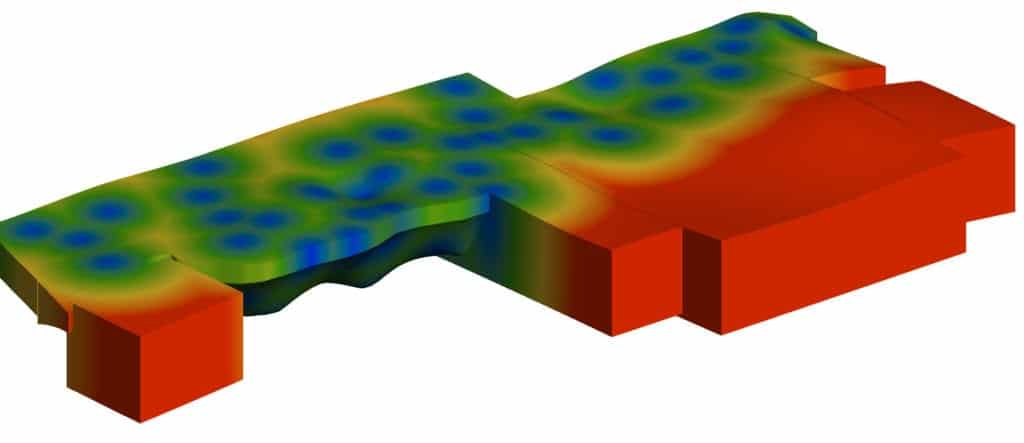

- Minimising remediation costs – determining the exact volumes of different contamination levels and minimising estimated disposal costs.

- Improving communication – visualisation of the landfill and all related contaminations on the property, to improve project communication between all stakeholders, including the SAGA Group, (purchaser and builder), City of Hamburg (owner), State Ministry for Environment and Energy Hamburg, (environmental control).

- Understanding digitisation benefits – determining the benefits of digitisation of results and workflows to advance BIM implementation.

Minimising Remediation Costs

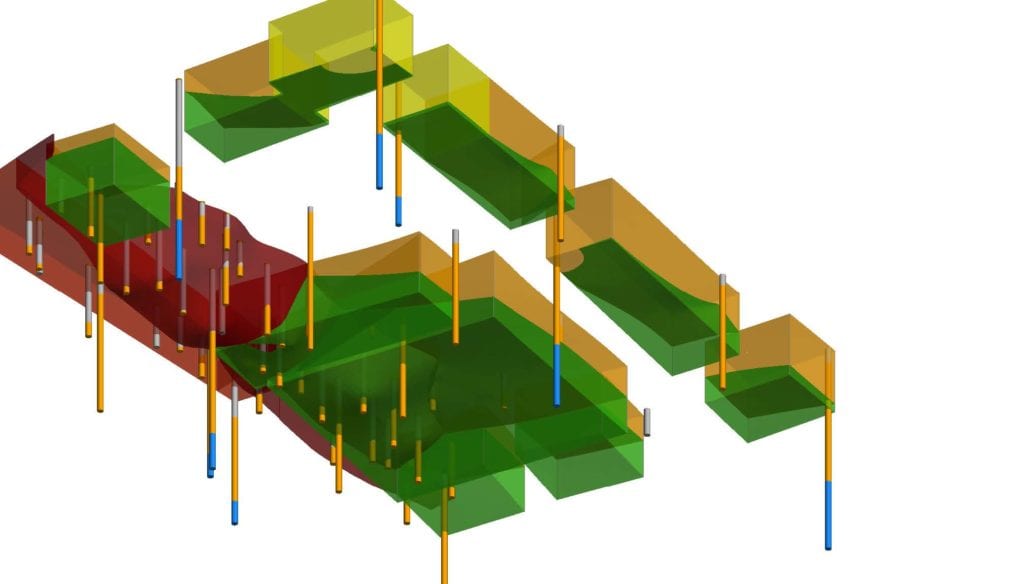

By easily combining 3D models of the contaminant zones with the geology and proposed site excavations, the Leapfrog Works model determined exact volumes of overburden and different contamination levels, culminating in the disposal concept. The 3D model was able to visualise all existing data and represent the landfill, depicting all relevant chemical delineations. This will also identify and classify disposals according to German Regulations, such as LAGA (State working community – waste) or DepV (Landfill regulation), to allow for safe and economic disposal. Tobias Querfurth comments, “We were able to perform a mass calculation using the solids from the 3D model, which enabled us to significantly reduce the

expected disposal costs.”

This clarification is essential before property transfer, to identify which areas and volumes of the landfill are to be excavated for the new buildings, which areas must be disposed of, and who is responsible for the cost.

We were able to perform a mass calculation using the solids from the 3D model, which enabled us to significantly reduce the expected disposal costs.

Improving Communication

As in every building project the communication between all stakeholders and parties involved is key for success. Tobias Querfurth explains, “We often see that our geotechnical results, which are important in the early stages of a project, only receive full attention in late planning phases. If further investigations or changes to plans have to be undertaken in these phases, costly project delays can quickly occur.”

The aim is that Leapfrog Works will provide the central ‘communication-platform’ for the stakeholders at the beginning of the planning phase.

This 3D visualisation will help ensure a smooth and transparent communication and information exchange. Importantly, as Leapfrog models are built directly from data, they can also be readily updated as new project data is added. This will enable better decision making throughout the project’s life cycle.

Tobias Querfurth comments, “Leapfrog’s dynamic nature means that we are easily able to update the model when new exploration data is available, which helps us get a quick overview for timely decision making, such as identifying areas where more investigations are needed. This visualisation also provides a general project overview that we can share with other stakeholders for better communication and understanding.”

Being able to share visualisations at an early stage with other project teams will also help spot gaps in information at an early stage and further save costs.

“Visualisation of the abstract data provides us with a better project overview for smooth and transparent communication. Sharing visualisations early in the project with other teams allows us to identify if

there’s enough data for their work, reducing the risk of time consuming and costly supplements that could be needed later on. As we’re also able to easily import and visualise new data, decisions can be made faster. And as the project progresses, we can easily involve other stakeholders who don’t have Leapfrog Works, using the viewer tool or IFC interface,” explains Tobias Querfurth.

Greater Productivity

Aside from the compelling and clear communication that Leapfrog enables, there were other distinct efficiency benefits gained from its use. A comparison was undertaken with the existing 2D method to get an early appraisal of the 3D approach. The estimation revealed that the 3D approach took half the time of the 2D method producing virtually the same results. Tobias Querfurth explains, “When we started modelling the site, a colleague undertook this in the traditional 2D method, and I modelled in 3D using Leapfrog.

The resulting models were surprisingly similar in accuracy, however, the Leapfrog model took roughly half the time to complete. The 3D approach was not only twice as fast as 2D, but it gave us much more clarity from the start of the project. A 3D model is also much easier to share with a non-technical stakeholder as we tend to imagine in 3D. We’re able to readily discuss it and make decisions. We are still working with some analogue processes which are time-consuming by comparison. In the future field data will be gathered digitally – only then will the full-time savings be achieved.”

The 3D approach was not only twice as fast as 2D, but it gave us much more clarity from the start of the project. A 3D model is also much easier to share with a non-technical stakeholder as we tend to imagine in 3D. We’re able to readily discuss it and make decisions.

Tobias Querfurth, M.Sc., Geological Engineer, Lieberman Engineering

Outcome

The first part of the project, the geotechnical report, has been completed following the key exploration work, which included drillings, Dynamic Probing Heavy (DPH), prospecting with mini-excavator sand groundwater samples. The disposal concept has also recently been completed and will be fine-tuned once lab reports on soil samples have been returned. This will include adding small refinements to the data held in the model, such as the soil categorisations and editing the vast amounts of chemical substances – e.g. lead, copper, polycarbonate. Once again, these changes can be readily incorporated within the Leapfrog Works model, automatically updating it with the new findings.

Tobias Querfurth concludes, “We intend to hand over the project results both as traditional 2D reports and the digital 3D model. To ensure interoperability of data for all users the 3D model will also be provided as an IFC file. Through the use of the 3D model an improved communication platform can be provided for the later execution phase. It is our hope that this project will create a digital standard for Lieberman Engineering and will lead us to favour digital processes going forward.” Although remediation work is currently assigned to another consultancy, the model can also add further support to planning at this final stage, providing an entire project lifecycle solution.

Seequent’s Civil & Environmental Product Manager, Pat McLarin, comments, “Leapfrog Works is the only dedicated solution that addresses the needs of the industry to dynamically model geology and contaminant zones while seamlessly interoperating with BIM workflows. It’s intuitive, easy to learn and cost effective, which means users can quickly upskill and, because they don’t need to rely on CAD expertise, can apply it to all sizes of projects, not just large ones.”