A new 3D geological model for InterCement’s Doña Amalia mine in Argentina is improving day-to-day operational decisions and assisting the company with long-term mine planning.

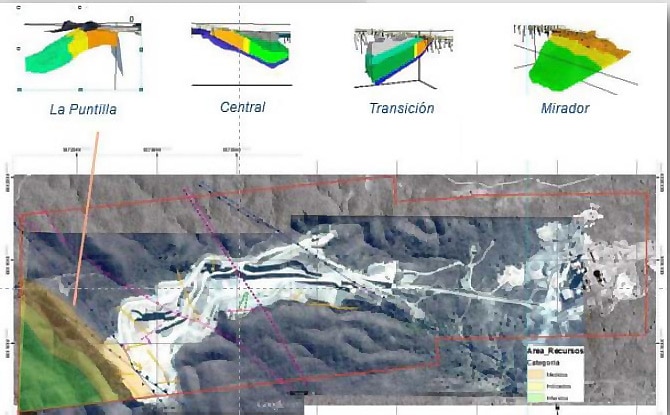

The model allows for greater accuracy in resource definitions, including limestone classifications within four separate domains that have different carbonate grades and structural settings, according to a paper presented by InterCement geologist Javier Pellegrini at the Inter-American Cement Federation’s annual conference in September 2015.

Located in northern Argentina, Doña Amalia opened in 1980 and currently produces 1.6 million tonnes of cement annually from an open pit about 2,300 metres long and 1,000 metres wide.

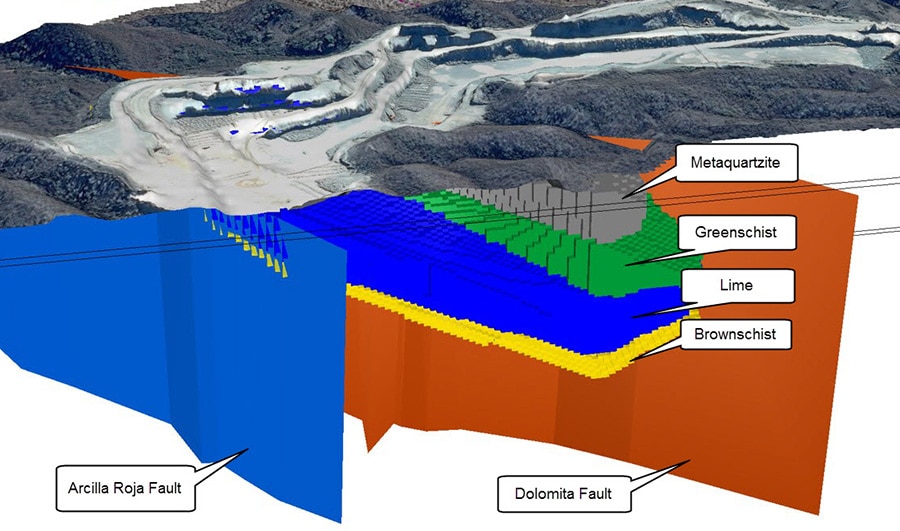

The deposit’s stratigraphy consists primarily of dolomites, limestones and shales and has been affected by several orogenic cycles, resulting in a complex structure of folded and faulted rocks. The presence of disseminated and vein quartz produces variations in the lime saturation factor (LSF), a parameter used by the cement industry to measure the ratio of calcium oxide to the other three main oxides (iron, aluminum and silica).

“The mine is structurally and geochemically complex, so it was important to integrate geological, geochemical and structural data in three dimensions,” says Pellegrini. “And as we get new information from surface or subsurface drilling and/or geophysical methods, we can incorporate it, strengthening the initial model to better reflect the reality of deposit.”

To build the model, Pellegrini and his team started by running quality control on the mine’s topography, adjusting contours based on a survey conducted over the mine in November 2014. Then, using wireframing tools in Esri ArcMap to integrate satellite imagery and the results of the field survey, they outlined the main geological structures. The fault plans were used as structural controls to delimit the four domains for geological interpretation.

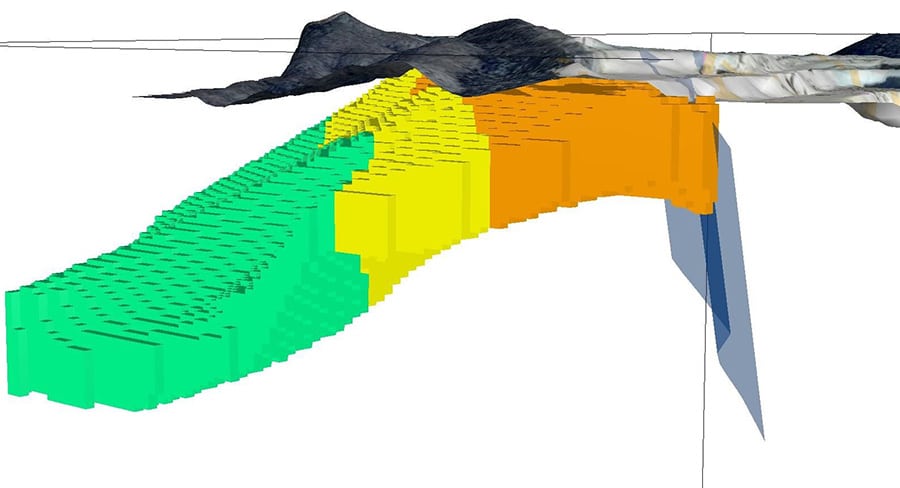

A drilling campaign of 43 drill holes over close to 3,000 metres provided further information about lithological contacts (particularly between the limestone and the brown shale basement rock), the thickness of the overburden, the quality of the limestone and the distribution of calcium, aluminum, iron and silica oxides. Any unreliable information from historical drilling, including dubious drill hole coordinates or holes with incomplete lithological data, was rejected.

The team created the 3D model by integrating the results of surface mapping with 20 vertical drill sections generated in Geosoft’s Target for ArcGIS and connecting the interpretations using wireframing tools. Limestone resources were categorized as inferred, indicated or measured depending on the Australasian (JORC) code for reporting ore.

“By outlining the four structural domains of the mine, we were able to quantify the average, minimum and maximum LSF for each domain to guide the mix of materials for processing,” says Pellegrini. “And in terms of strategic planning, the model and resource categorization will help us to evaluate other deposits we may consider for purchase.”

He says the 3D geological model created for Doña Amalia is an innovative new tool the cement industry can use to support and improve mine planning in the short, medium and long term.