The Project

The Scoggins Dam at Henry Hagg Lake near Gaston, OR, supplies local businesses, farms and about 400,000 people with municipal and irrigation water. The dam is a Federal facility, owned and operated by the Bureau of Reclamation. The dam is currently being evaluated for dam safety modification, along with additional water storage, and is a joint project between Reclamation and Clean Water Services. Architectural, engineering, and consulting firm HDR, was contracted by Clean Water Services to provide a feasibility design study for building a new Roller Compacted Concrete (RCC) dam at a site downstream of the existing dam. This site is a more favorable location that would provide increased storage capacity and significantly reduce risk of failure due to a large seismic event that has only recently been understood.

HDR used Seequent’s dynamic subsurface modelling solution, Leapfrog Works, to assist with the investigation, the geotechnical design report and to estimate cost and develop the preliminary design drawings.

HDR’s Geotechnical Engineer, Andrew Little, comments, “Leapfrog Works allows for a quick and user-friendly way for the geologist to directly develop a 3D model which can be examined and reviewed very quickly. It also allows for fast and elegant communication of the model to other team members and clients via cross-section layouts, and slicing the model to display it in real-time.”

Situation

Scoggins Dam and Reservoir are situated on the eastern slope of the north-trending Coast Range of northwestern Oregon. This portion of the eastern flank of the Coast Range is a northeast-dipping monocline consisting of marine volcanic and sedimentary formations of Tertiary age.

As knowledge of plate tectonics evolved in the 1970s and 80s, subduction zone mechanisms and resulting earthquakes became better understood. The possibility of a magnitude 9 or greater earthquake off the coast of Oregon and Washington led regulatory agencies to look at vulnerable infrastructure. The Scoggins Dam is an embankment dam built out of materials that are susceptible to cyclic strength loss during a major earthquake and would need modification to avoid failure during a subduction zone earthquake.

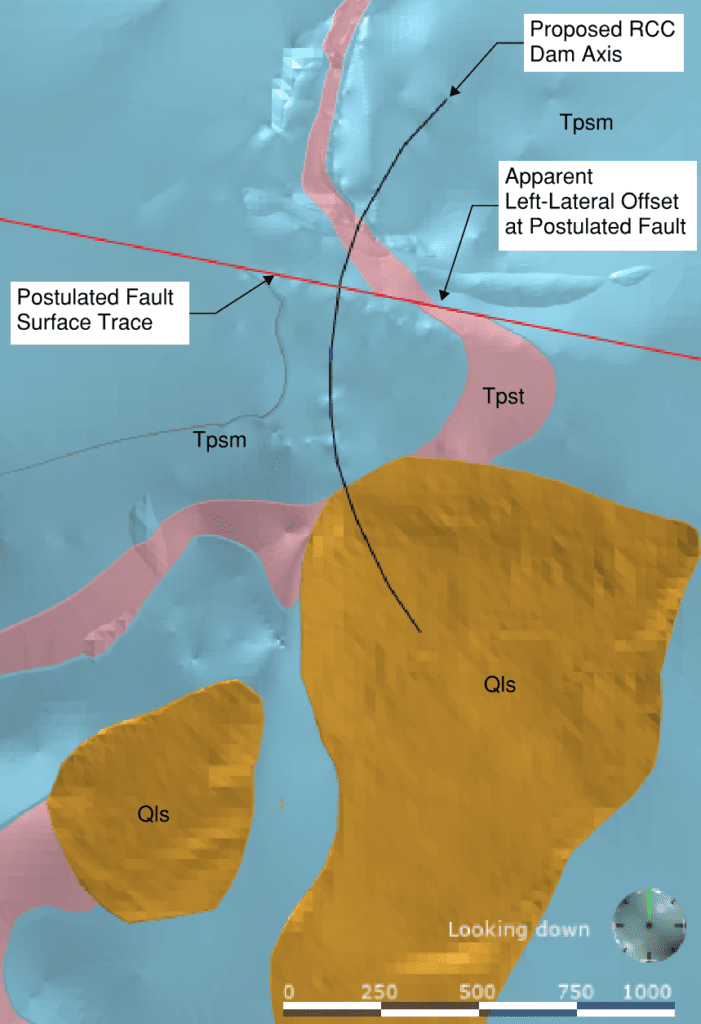

The goal of the project is to provide safe storage and a resilient water supply that will not be lost during a subduction zone earthquake. The project is on-going. HDR is scheduled to complete feasibility design in December 2019 for one of the three options under consideration: building a new RCC dam. The Bureau of Reclamation is working on the other two options; to fix the existing dam without providing any additional storage, and to fix the existing dam and raise it for more storage. Reclamation and Clean Water Services will jointly decide which one of three options to carry forward to final design. Andrew Little comments, “A major challenge was developing a geologic model utilising only 20 borings over a large, approximately 30 acre, area with almost no outcrop to verify the geologic structure. There was a significant difference in the bedding dip on either side of the valley that had to be explained, as well as a marker bed through the site evident in the boring data that was not planar. The initial postulation was that a fault runs through the site but there had been no evidence in either boring data or geophysics to support this theory.”

Response

HDR chose to use Seequent’s dynamic subsurface modelling tool, Leapfrog Works. The tool helps users understand geological risks through 3D visualisation which can then be more accurately communicated to all stakeholders through a range of sharing and collaboration tools.

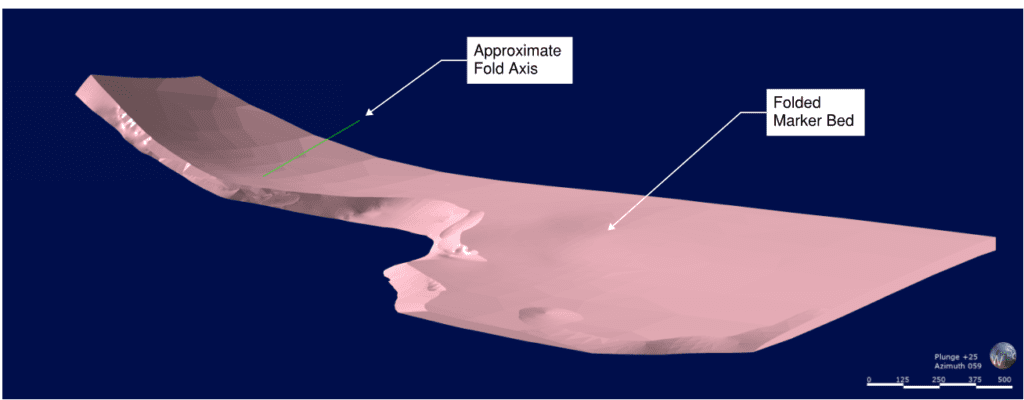

Andrew continues, “We used Leapfrog Works to model the marker bed with the structural data obtained from down-hole televiewers, this provided a 3D visualisation of the folded marker bed and revealed a fold axis that coincided with the regional tectonic pressures. This provided an explanation for the variability in bedding orientations across the valley other than a fault through the proposed dam site. The Leapfrog Works 3D model provided a visualization of the folded marker bed that would have been difficult to interpret and communicate using 2D cross-sections alone.”

To model the shape of the marker bed; structural data pertaining to the average bedding orientations within each boring the marker bed unit was encountered and was applied to the stratigraphic contacts using the Leapfrog Works structural data feature. Additional structural data from surface mapping at a few exposed outcrops was also used to provide the shape and trend of the marker bed.

In the past HDR developed their geological model using cross-sections in Civil 3D. However, this process had proved to be time-consuming and prone to errors and ultimately only provided tiny windows into the subsurface via a few cross sections scattered throughout the site.

Andrew explains, “Surfaces could be developed in Civil 3D to interpolate between cross-sections but the task was laborious, requiring a CAD technician to work with the software while a geologist reviewed the outcomes.”

Leapfrog Works is crafted for geologists and has a user-friendly interface and intuitive workflows and tools. The geologist is able to develop a 3D model themselves, without the need for a technician, enabling quick review and analysis in the 3D scene. Andrew comments, “When I was learning Leapfrog Works I noticed that it is a lot more aligned with other software and is much more intuitive. If you don’t use Civil 3D every day you have to re-teach yourself. It’s nice to use a software that’s intuitive from the start.”

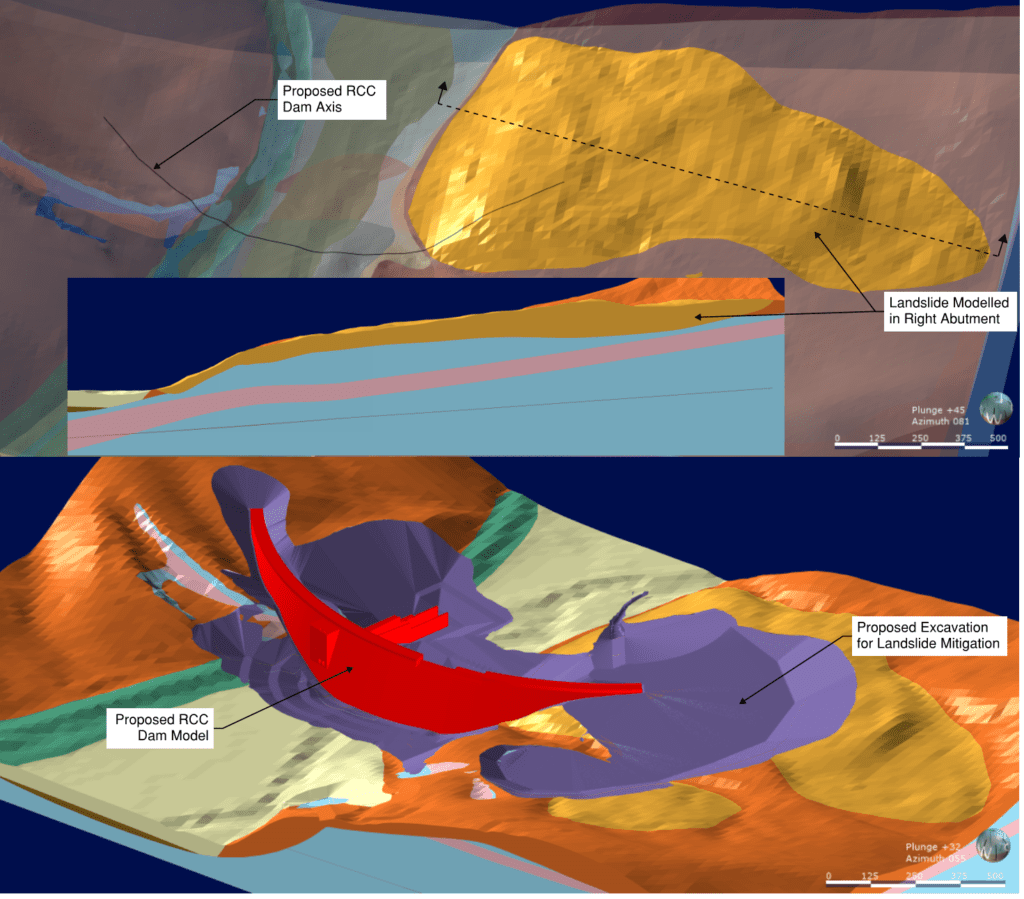

Understanding the geology

Leapfrog Works was used to create a comprehensive 3D subsurface model of the project site that included a large landslide, as well as analyse for the potential of faults by adding hypothetical data scenarios. One important aspect to the feasibility design effort was understanding and accurately modelling a landslide in the slope above the right abutment of the proposed RCC dam in order to inform the design decision to mitigate landslide risk to the proposed dam. Leapfrog Works software was helpful in modelling the extents of the landslide and the subsurface slide plane based on field data and cross-sections taken directly from the model for slope stability using GeoStudios Slope W software.

The Leapfrog model was also used to evaluate the possibility of faults through the site since it is located within a large, complex, active fault zone. A postulated vertical fault through the valley was created in the model to evaluate the possibility and magnitude of offset based on the collected field data on either side of the modelled fault. Apparent left lateral offset was shown in the model and the possible magnitude was used to inform mitigation efforts in the design.

Volume quantities were used to verify Civil 3D calculations and excavation and design models were imported to visualise the potential changes to the site in 3D. Designed specifically for the industry, Leapfrog Works is interoperable with industry-standard ground investigation data formats. Geological models can also be combined easily with engineering designs, BIM workflows and groundwater flow models, to streamline workflows and efficiency.

The ability to import excavation surfaces directly into Leapfrog Works was especially useful, as Andrew explains, “We found it much easier to see errors that need correcting in the solid Leapfrog Works model as opposed to viewing surfaces via contours or triangles in Civil 3D.”

Outcome

Using Seequent’s solutions, HDR were able to gain distinct time saving and communication advantages. Just setting up the basic model in Leapfrog Works took days, as opposed to weeks in Civil 3D.

Not only was significant time saved in creating the Leapfrog Works model but the end product was much easier to use to quickly communicate aspects of the subsurface. Andrew comments, “You can do so much more with Leapfrog Works. Also, certain features of the data may not have been evident if only seen in one or two dimensions. 3D really adds value in understanding the geologic features.”

Next stages

There are various consultative steps required over the coming months before Reclamation and the Clean Water Services Board make their final decision on the dam modification, in summer of 2020. A key milestone is risk evaluation of all three options, which will occur later in 2019. Because of the accessibility of the 3D models, they will be used at this stage to communicate key aspects of the HDR design. Andrew comments, “We’ve already been able to show the models to the Bureau of Reclamation, which has been very useful.”

There is also the option to use the free Leapfrog Viewer software, which allows the viewing of scene files exported from Leapfrog models, a great way to share 3D model views in public and stakeholder meetings for clearer communication. Leapfrog Works offers a variety of different outputs and sharing and communication tools from rendered model stills to the new online web tool, View, which also allows for model views to be embedded in websites, which is useful when consulting with public groups.

Going forward, Leapfrog Works will be used for all future projects by geologists in HDR’s Denver office. Andrew comments, “I have been reaching out to our West Coast offices to get them familiar with Leapfrog Works’ capabilities as we’ve been so impressed with its use during this project that we would like to develop best practice modelling around its use.” Seequent’s Civil & Environmental Product Manager, Pat McLarin, comments, “Leapfrog Works is the only dedicated solution that addresses the needs of the Civil Engineering and Environmental industries. It’s intuitive, easy to learn and cost-effective, which means that users can quickly upskill and don’t need to rely on CAD expertise. Understanding and communicating subsurface conditions is key to a project’s success, by harnessing the power of Leapfrog Works geological, environmental and engineering data can be readily visualised and shared in 3D for better decision making and reduced risk.”