Hundreds of multimillion dollar wells make high temperature geothermal projects a major investment. New technologies that cost up to 25 times less – both in money and space – are helping to fill green energy gaps.

Ruden Energy has created a low temperature geothermal system that can make 10 wells generate the same heating and cooling capacity as about 250 wells in a traditional model.

“The risk is very low compared to the potential gain. I mean the calculation of how much our investigations are compared to if you had to drill 100 more wells: That’s a lot more expensive,” says Sunniva Morris, well site geophysicist at Ruden Energy.

Her team’s projects are expanding in Norway where funding for innovative technology gives clients an incentive to develop resources. Unlike other renewable energy sources geothermal provides a consistent source of energy: rain or shine, wind or calm.

More heat, less effort

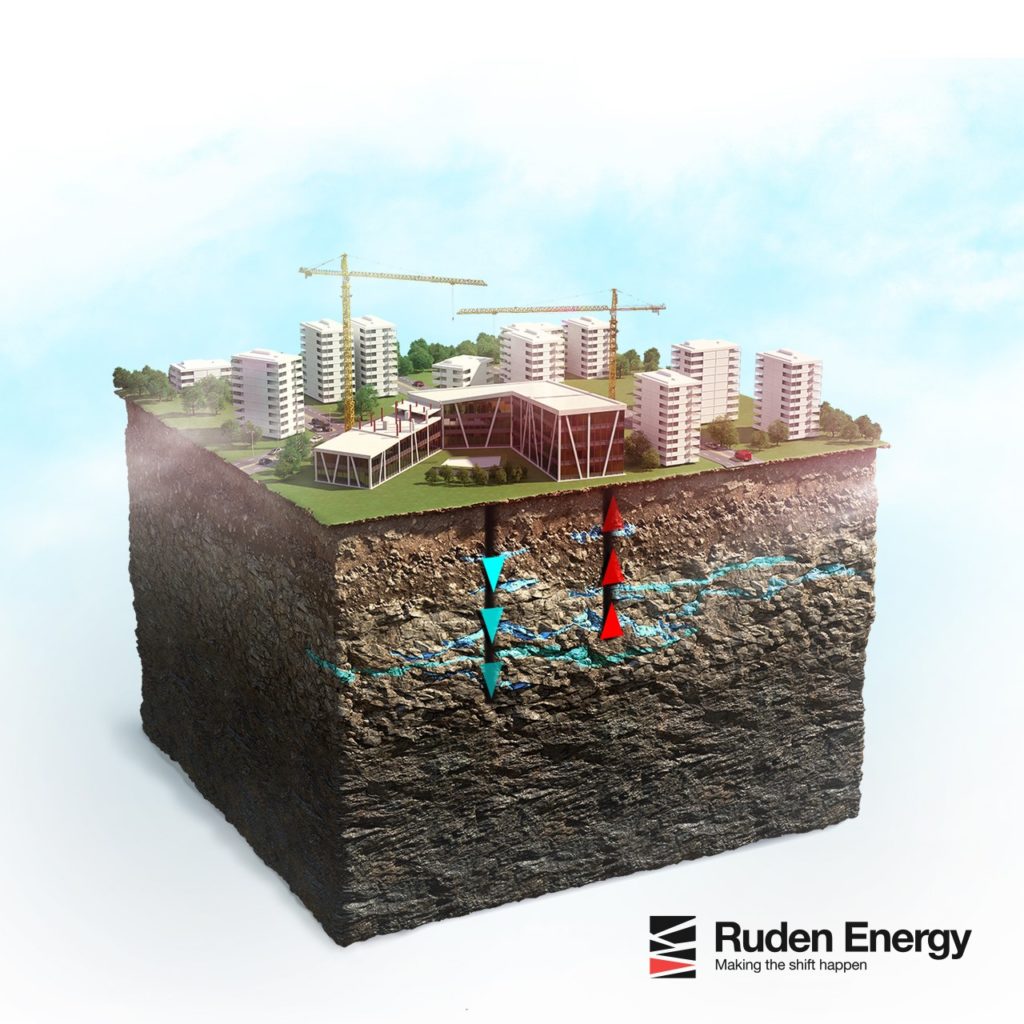

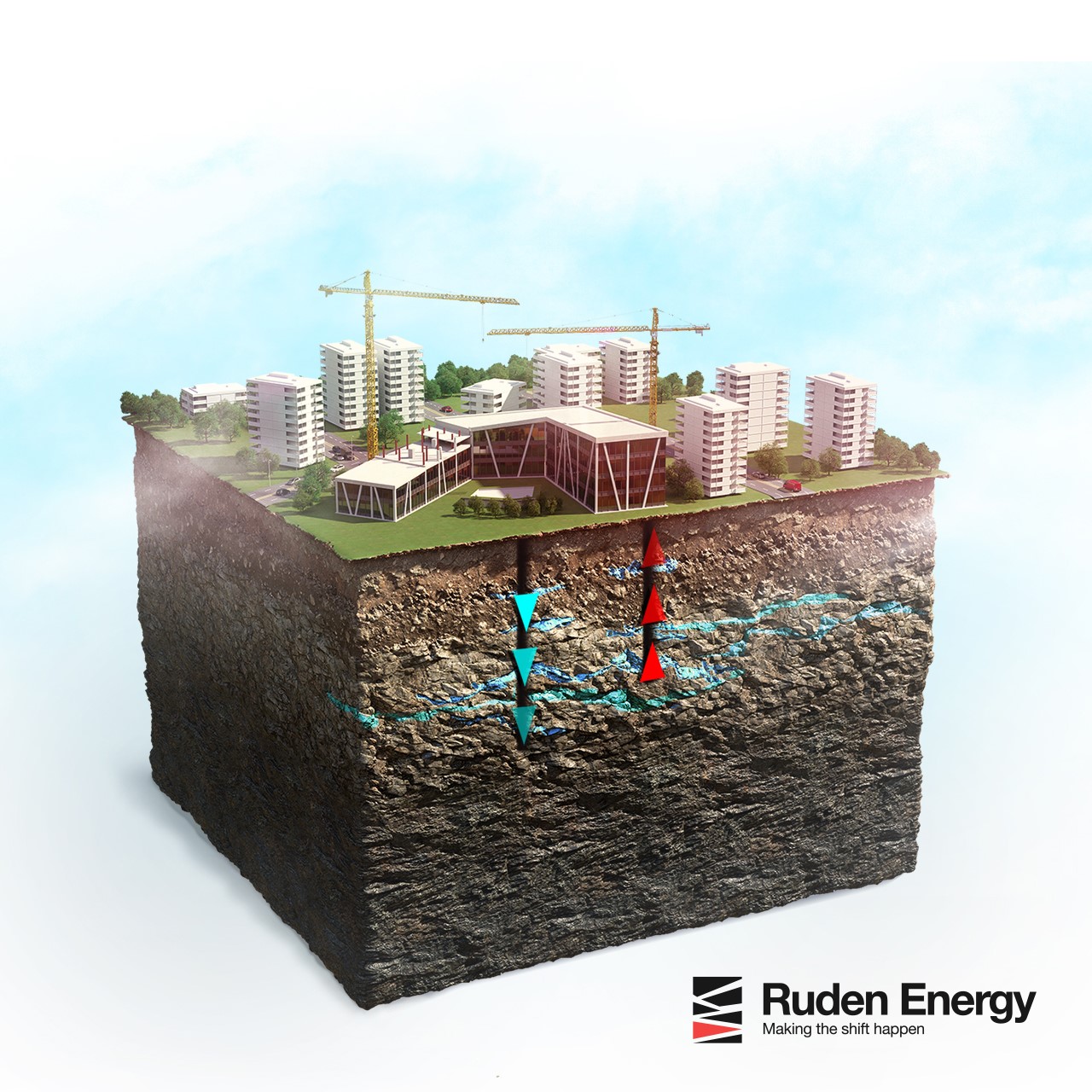

Many traditional geothermal systems use closed circulation well technology. You drill one well into the earth, run pipes down, and then circulate a fluid up and down through the same well to transfer heat from the subsurface to the surface.

The volume of heat-carrying fluid and the bedrock it can contact is limited by the size of the well.

“Instead of that, we circulate water down in one well and through the fractures in the ground, and then up through another well,” Sunniva explains.

Their LEAT (Low Enthalpy Aquifer Technology) system essentially creates a river underground by pushing water horizontally through natural cracks in the bedrock.

Since there’s more surface area for the water to be in contact with the bedrock, more heat is drawn out of the earth.

“The contact surface between the rock and the water, which is used to transport energy, is much bigger than it would be in just a pipe within a well,” says Sunniva.

“Because of that we’re able to use just 10% of the wells compared to what they need in traditional closed systems for the same amount of energy.”

Connecting the cracks

The biggest challenge for LEAT is connecting the fractures between each well, ensuring they connect and are large enough.

“It helps to visualise it. We’ve always known: Oh, here’s a fracture in this well. And, here’s a fracture in that well. But it’s impossible to connect it visually if you don’t have this kind of program.”

To see the subsurface, LEAT projects use a variety of well logging techniques as well as geophysics, such as natural gamma ray and resistivity surveys. Sunniva herself is a geophysicist who works on mapping those fractures.

“I load everything into Leapfrog, for example, the natural gamma ray signal. Then, I see where the same rock formation is in each well and I connect the wells to make a geological model.”

All techniques combined into a single model provides her team with insight into the unseen subsurface world below, removing a lot of uncertainty.

As well as geophysics and geology modelling, water is what carries geothermal energy. Thus, it’s vital for Sunniva to provide conceptual models to hydrogeologists to determine – How powerful will the flow rate be at one fracture? How could stimulating the fractures affect it? How long could the flow be sustained over time?

“We’ve actually started our first project now where I’ve finished the geological model in Leapfrog and I’ve sent it off to one of our hydrogeologists who is going to integrate it into FEFLOW,” says Sunniva.

Finding heat beneath

Drilling geothermal wells can be expensive. Thus, anytime you drill a well you want it to work.

The initial targeting phase is risky and having wells fail to produce is not uncommon.

“Some wells give 10 liters per second, which is great. And then you have some wells that maybe give half a liter per second, which is terrible,” says Sunniva.

“Often, it’s based on location and we try to predict where to drill to get to find the best well. Obviously, it’s not easy but it helps a lot to have the modeling software.”

Sunniva’s team uses a mixture of geophysical surveys, geological techniques, and hydrogeology to select well targets. Through these techniques, they can see inside the earth’s subsurface and know where to drill.

Layering the data helps them evaluate areas of interest – where more cracks, heat, or water are likely – and make connections between data points.

“I think without Leapfrog, I don’t know how we would place the wells,” Sunniva explains.

“It’s super good for well planning, you just pick where you want the well and you see if it intersects the fracture.”

Cutting the risks to drilling wells by selecting targets based on all available data helps her team avoid or find ways to stimulate poor performing wells.

Saving geothermal

LEAT is a relatively new technology. The Ruden Energy team has been proving it project by project and gaining traction. Yet, most of their clients come from a surprising source – failed geothermal projects.

“They try this other closed circulation well technology, but that fails. Then, they talk to us after. So, we’re the ones who save the traditional projects,” says Sunniva.

“We’ve been able to save quite a few projects through that because otherwise they would abandon the projects or get much less energy.”

Some projects drilled 100 wells before realising there wasn’t enough space or that there was too much water. LEAT technology requires a fraction of the wells (thus much less space), and as for water:

“In traditional systems, large amounts of groundwater mostly cause problems and failure. But for us, a lot of water is good because that means we can circulate more water through the fractures.”

LEAT thrives under pressure and is flexible enough to be used across many landscapes.

“Even if the fractures aren’t that open in one area, we can stimulate them to make them produce more. All you need is crystalline bedrock, which we have lots of in Norway” Sunniva explains.

Using the earth as a battery

LEAT isn’t the only way geothermal is evolving in Norway. Ruden Energy is also testing their latest concept HEAT (High Enthalpy Aquafer Technology). This system focuses on capturing energy from an unexpected source – industry.

“We want to store heat from a combustion plant, where they burn the waste and create energy. By storing the excess heat that they produce in the summer underground to use it again in the winter, this energy does not go to waste and can be used when it is actually needed.”

Water would circulate through the plant, heat up, and then pumped underground into the bedrock to be stored until needed.

Sunniva enjoys being part of the future of geothermal energy, making it more adaptable, affordable, and accessible:

“You save money, you save the environment, everyone wins.”