Providing a comprehensive monitoring strategy for tailings dams requires a more holistic view, with the focus on monitoring data and linking back to original assumptions. Using GeoStudio SEEP/W as part of this strategy, AECOM is delivering a safer, more collaborative approach for better decision-making.

Luke Clarkson, who graduated from his doctoral studies in 2021, conducted a series of theoretical and case study works as part of a thesis on developing a comprehensive monitoring strategy for tailings dams.

In 2020, a research project was undertaken at an unnamed Australian gold mine to help understand the influence of external conditions on the phreatic condition, and how and when these changes might reflect at discrete piezometer locations.

As there is a delayed effect in the propagation of pore pressure changes in a tailings dam, GeoStudio SEEP/W was used to facilitate this transient analysis. A powerful finite element solution for modelling groundwater flow in porous media, SEEP/W allows users to model simple saturated steady-state problems or sophisticated saturated/unsaturated transient analyses, such as seepage through complex upstream tailings dams.

“Using the calibrated model, we have a more holistic understanding of our tailings dam,” says Luke.

“By mirroring the practical data in the theoretical model, we can refine the assumed design parameters according to behaviour over a long period of time. A tailings dam is a unique, changing environment that is built iteratively and contains variable slurry material, not pure water. The transient analysis capability of SEEP/W was critically important.”

The phreatic condition in tailings dams and deposited tailings responds differently because of material permeability and changes in external conditions. It is important for operators and designers to understand these changes and their reflection on discrete piezometer locations.

Pore pressure changes induced at one location in the tailings dam can take a significant amount of time to propagate to a given piezometer location and hence a delayed effect could be expected. Understanding this transience is key to ongoing management.

Better management of tailings

The new Global Industry Standard on Tailings Management guidelines, introduced by the International Council on Mining & Metals (ICMM), are putting the responsibility on operators to better manage their tailings.

With data sourced from Todd Armstrong, Associate Director – Dams Engineering at AECOM, from a gold mine site in Australia, Luke developed the numerical model using GeoStudio SEEP/W based on existing conditions and dam arrangements.

The model’s initial goal was to mirror what was happening on the mine site. Piezometer installations and measurements were compared against numerically modelled scenarios, calibrating the model against in-situ performance. In turn, this allowed assessment of the sensitivity of phreatic conditions against hypothetical changes to the tailings dam environment.

“The feature that led me to use GeoStudio was the SEEP/W capabilities in transient analysis,” explains Luke. “We can model a changing water level over time, which in a tailings dam situation is very important.”

Overcoming the sensitivity challenge

The biggest challenge was the number and sensitivity of parameters that affect the phreatic condition, as the tailings dam environment is so sensitive.

“We had the practical answer that we were trying to get to from the piezometer data, so we were trying to simulate that instead of starting with the theoretical and assessing what you think will happen,” explains Luke.

“We were backtracking, we had to get it as representative as possible. This meant a lot of back and forth to match output to input. But, despite the iterative nature we got to a point where we were happy with the model. To get a trend that was close to what we were seeing on our piezometer readings was a relief but also impressive.”

Calibrating the model

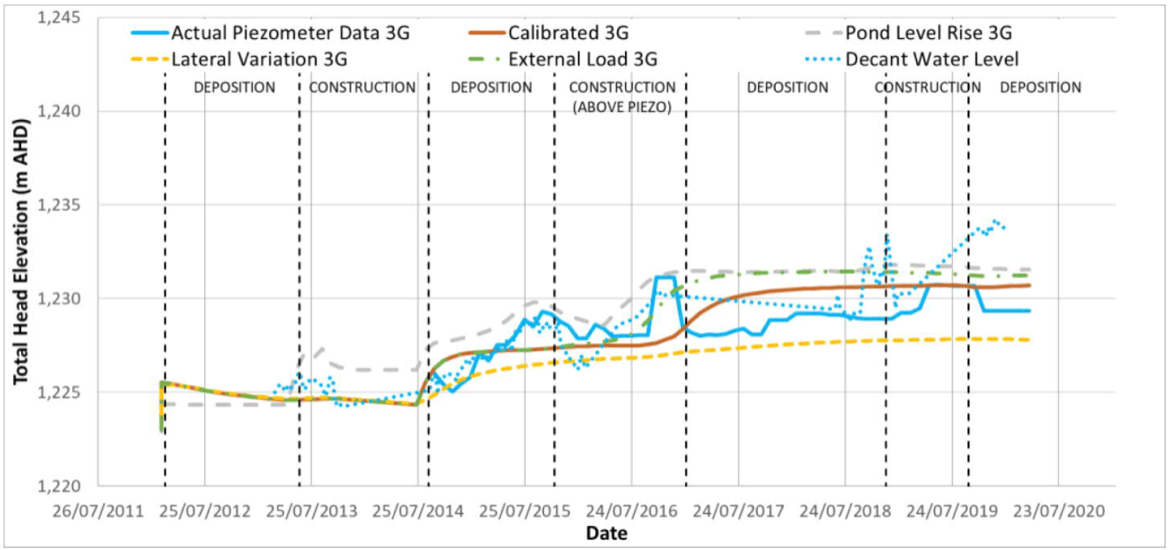

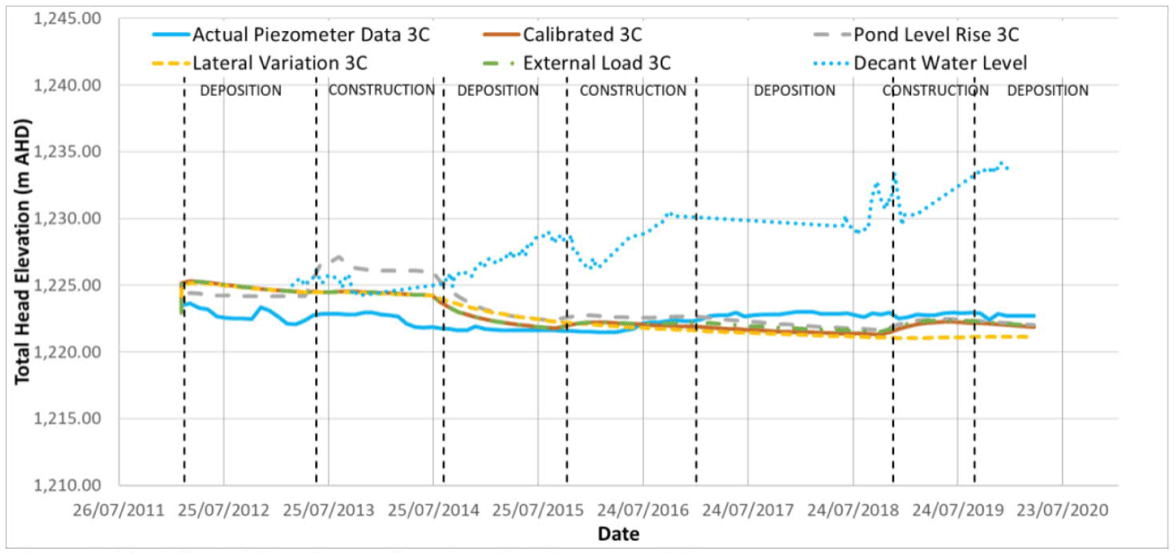

Calibration of onsite piezometer measurements with pore water pressure modelling in SEEP/W allowed consideration of the hypothetical effect of pond level rise, lateral variation of hydraulic conductivity, and the introduction of an external load on tailings dam pore water pressures.

This is shown in the below figures. The ‘actual piezometer data’ plot is generated by the piezometer readings onsite: ‘calibrated’ shows the modelled seepage profile, while the ‘pond level rise’, ‘lateral variation’ and ‘external load’ reflect the different external condition scenarios.

The overall magnitude of the change in total head elevation was generally achieved, and the modelled response was within 3.7 m (inclusive of data spikes) or 2.2 m (not inclusive of data spikes), when comparing onsite piezometer readings against elevation levels generated within the calibrated model.

Understanding dam performance

Luke’s research combined with AECOM’s design allowed for calibration of the model, mirroring the practical data, to provide a better understanding of the tailings dam as a whole and minimising risk.

The research showed that, when considering true tailings dam performance, it is important to understand that the measurement may be in real time but the condition being measured has a delayed response to pore water pressure changes. The external conditions considered (pond level rise, introduction of an external load, and variable lateral hydraulic conductivity) increased the total head elevation at piezometer measurement points when compared to field data. It was suggested that different external conditions reflect different total head elevation behaviours. Practitioners are also able to repeat the approach based on the guidance within the research paper, tailored to their unique sites’ datasets.

Improved collaboration to achieve high standards

The model enables better collaboration between designers and the onsite operators. The approach also ensures best practice and helps to fulfil obligations regarding the new ICMM global tailings guidelines.

The demand – and, in turn, the associated risk – for tailings storage is increasing exponentially with time. Through access to and the use of the appropriate design and construction, and operational and monitoring approaches, tailings dam practitioners can be more readily equipped to understand and assess the deterioration of their unique tailings dam structures.

“Validating the assumed design model means we apply what we’ve learned over years for better understanding. The way the tailings dam industry is heading, there’s a lot more focus on monitoring data and instrumentation and linking them back to the original assumptions, rather than treating them as segregated parts,” says Luke.

“When the dam goes into operation, many stakeholders will look at the monitoring data before they will go back and look at the original design or assumptions. Marrying these together gives a more holistic view. It allows for a safer, collaborative approach between stakeholders and enables informed discussion and decision-making.”

Sources:

The research was part of a PhD research topic with the intent to leverage global contacts and previously derived knowledge to advance understanding of tailings dams monitoring strategies.

Read the full thesis here.

https://www.researchgate.net/publication/352983518_Comprehensive_Monitoring_Strategy_for_Tailings_Dams