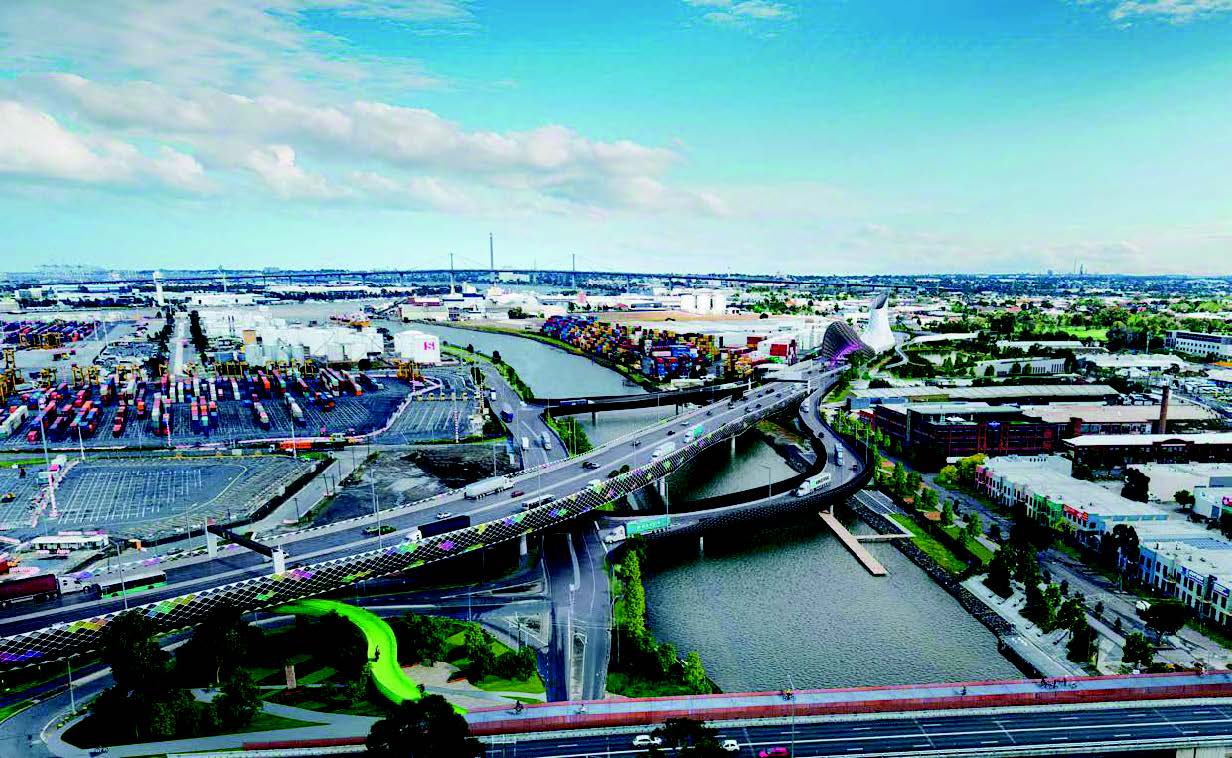

The West Gate Tunnel project in Melbourne, Australia is one of the largest diameter bored excavation projects in the world and the largest ever undertaken in the southern hemisphere. Globally renowned Geotechnical services firm, Golder Associates, were engaged by Transurban, (who partnered with the Victorian Government to build the tunnel), to undertake an assessment of the tunnel project. For the first time, Golder used ground engineering 3D implicit modelling solution Leapfrog Works to assess geological risk and communicate that risk to a variety of stakeholders as well as to convey information to design and build tenderers.

The project is significant due to the two purpose-built mega sized Tunnel Boring Machines that will be used to build twin tunnels between the West Gate Freeway and the Maribyrnong River. These machines have a 15.6 m diameter cutting head and will be used to excavate twin, three-lane tunnels.

The cost of the Case study: Tunnel vision – Leapfrog Works gives confidence to critical decisions in Australia Infrastructure project is significant, estimated to be in excess of AU$5.5 billion and it is, therefore, essential to establish a thorough understanding of the geological risks to minimise impact on the project’s progress, cost and success. Following ministerial planning approval, construction is now underway.

“3D visualisation allows the relationship between the old creek bed and the proposed tunnel to be clearly understood.”

Scott Ambridge, Golder’s Senior Environmental

Engineer

The West Gate Tunnel Project will deliver a vital alternative to the West Gate Bridge, providing a much needed second river crossing, quicker and

safer journeys, and will remove thousands of trucks from residential streets. The project is anticipated to generate over 2 million (bank) cubic metres of earth and rock spoil material during the construction of the 6km of tunnels and supporting road upgrades.

Golder was the technical lead for Geotechnical, Hydrogeological, Contaminated Land and Air Quality services and provided specialist input to procurement, reference design as well as the preparation of the Statement (EES) for the Project.

Golder carried out a thorough ground investigation with over 200 professionals working on the project during the two to three year period from inception to delivery. Professionals included field technicians, field geologists, hydrogeologists and geotechnical engineers. Investigations for the project were intensive and successfully delivered within a short time frame, with up to six drilling crews, plus trial excavations, geophysical survey and CPT teams on day shift and 3-4 night shift teams drilling along the busy West Gate freeway. The tunnel passes through variable sedimentary and igneous deposits of the Cainozoic (Quaternary & Tertiary) era. These deposits reflect the complex geological and geomorphological processes that have shaped the region, including tectonic movements and development of palaeo-valley structures.

Response

Golder made the decision to use Leapfrog to assist in a detailed assessment of the ground conditions. Built specifically for the Civil Engineering industry, Leapfrog Works provides a complete solution for fast and dynamic modelling of ground conditions, analysis of the interactions with the engineering design and intuitive 3D visualisation. Leapfrog is the leading geological modelling software in the mining industry where it has been used for over a decade and is relied on by all the major mining companies and consultancies. It uses a proven implicit modelling engine.

Golder’s Principal Geotechnical Engineer, Trevor O’Shannessy, says, “This was the first project where we’d used Leapfrog Works and our use has evolved since. We started by building the geological model in 2D using a very standard method and then we brought that 2D information into Leapfrog Works to build a 3D model. Going forward we’d start the project in Leapfrog Works. A team of three geologists worked on the geological model, with two key Leapfrog Works users who received minimal prior training with Leapfrog. Golder were impressed by how quickly the new users of the software came up to speed, only taking around 1-2 days to feel proficient.”

Trevor comments, “There were obviously some nuances here in terms of familiarity with similar products and specific ‘gnarly’ issues such as the best way to model a smooth base of Stony Creek but we were generally impressed with how user friendly Leapfrog Works is.”

Leapfrog Works fulfilled a number of critical project requirements, including:

- Highlighting uncertainty around the project’s

Southern portal. - 3D spoil volume modelling.

- Supporting the tender process by providing contractors with interactive 3D models.

- 3D modelling of aquifer units used in hydrogeological impact studies.

- Generation of 2D geological sections for geotechnical ground movement modelling.

- Use as a key communication tool with the client and at the State meeting.

Highlighting uncertainty at the Southern portal

The Southern east bound portal, the site of a former creek, had been filled in, moved and turned into a stormwater drain. Looking at the 3D outputs generated by Leapfrog Works, Golder geologists were instantly seeing an issue.

Scott Ambridge, Senior Environmental Engineer comments, “For me that was the trigger point to look at a more detailed model in that area. If you can imagine this snaking creek was crisscrossing the two very large tunnels as they go under a critical freeway asset.

Getting a sense for how those geometries interact was very difficult in 2d but in Leapfrog’s 3D environment we could see much more, such as looking at minimum cover and even what the material between the tunnel and the old creek bed was looking like. We could then determine the risks from a geotechnical point of view. Leapfrog Works gave a lot of clarity in that respect.”

The consequence of not uncovering this risk could have led to ground movement during tunnelling adversely impacting on the overlying freeway. Such a risk if left unmitigated may have damaged the main arterial freeway, potentially shutting it down with all the associated impacts on the project and on those who rely on it locally.

3D spoil volume modelling Golder used the 3D geological ground model and chemical results to develop an advanced 3D volume estimate for the 2 million cubic metres of spoil. As well as identifying contaminated soil and acid sulphate, they could identify material that could potentially be used for other projects. “The geology is complex,” explains Scott, “with multiple geological layers including two different volcanic units and different sediments types all sandwhiched together.

Due to pronounced variances in chemical weathering and erosional processes the geology changed significantly both laterally with depth. Using Leapfrog Works made the problem of volume estimation across

the multiple geological units much simpler.”

Sharing models to support the tender process A feature of Leapfrog Works is the free Leapfrog Viewer, which allows models to be readily shared without having to access the full software. Golder used the Viewer to share geological models with contractors in the tender process. Contractors were then able to interrogate the geological models and prepare and price their tenders appropriately.

Scott explains, “The contractors were able to slice through the model, rotate and spin it around and see where there was greater uncertainty because there was less information or where they needed more clarification. The successful contractor identified the increased tunnelling risk associated with the buried creek channel and they went deeper with one of their tunnels to minimize exposure to it. We understand that this contractor will continue to develop the model using Leapfrog Works.”

3D modelling of the aquifer geology

Leapfrog Works was used to model the aquifer geology, (spatial geometry and thickness of the layers), as a 3D model. The aquifer units were first modelled in GoCAD as the users had more familiarity with the package. The combined aquifer geological model was then utilised in FEFLOW, another software package, along with hydrogeological properties (permeability, storage, etc.) to estimate the potential impact with respect to groundwater drawdown and flow direction change.

“Slicing through the model quickly shows the importance of tunnel depth for the planned excavation.”

Scott Ambridge, Golder’s Senior Environmental Engineer

Leapfrog was used in combination with several other different software packages, incuding GoCAD and PLAXIS and was also used to rapidly import LIDAR surface elevation data from large .tin files.

As an illustration, Leapfrog was used to select and export 2D sections of the layer geology at critical points along the alignment as the basis for ground movement modelling in PLAXIS. Trevor explains, “This was particularly important in the area where the tunnel went below the West Gate Freeway and where the backfilled section of the former creek sat between the tunnel crown and the base of the Freeway embankment. Ground conditions were considered poor here, with greater uncertainty in respect to potential ground movement magnitude and we therefore needed to visualise the subsurface conditions and be confident about our interpretation of the subsurface model. As this area was targeted with numerous boreholes during the investigation Leapfrog provided a good interpolation tool in the 3D space and enabled the construction of a model in a relatively short period. It also allowed us to rotate the model, interrogate it in 3D and experiment with assumptions such as bed level and upstream/downstream gradient of the creek incisement.”

“Introducing Leapfrog Works at such a critical stage in the project had an immediate impact on both our understanding of the geology and our ability to communicate it. Scott Ambridge , Golder’s Senior Environmental Engineer”

Key communication tool

Leapfrog models were also used in client communication meetings with Transurban and State government advisors to demonstrate process and ensure key parties were satisfied. Golder used Leapfrog Works to develop a number of different outputs to help with this communication which included making use of Leapfrog’s movie function to produce an impressive fly-through of the proposed tunnels.

“We found that the fly-through helped clients clearly conceptualise,” says Scott. “With Leapfrog Works we have a breadth of different ways to convey what’s happening with the model and more scope, in the end, uses of the model as a key communication tool.”

The movie function has a high frame rate of up to 60 frames per second and works by dragging scenes into a storyboard with transitions added automatically, with the finished resolution going up to HD.

Outcome

As the tunnel approaches construction phase, it is understood that Leapfrog Works may be used by the appointed contractor to keep the model updated with new information and improve decision making. This ‘dynamic’ updating facility means that new data, gained from the field during excavation, can be readily loaded into Leapfrog Works and will automatically flow through to the end model and rapidly update it.

“This feature is particularly relevant in the construction phase,” says Scott, “To properly assess ground related risks as tunneling progresses it’s also a requirement under the project that ground conditions are continually reassessed and the model updated when new information come to light. Being able to quickly and easily refine the geological model in Leapfrog Works will be an essential tool.”

“Without a doubt introducing Leapfrog Works at such a critical stage in the project had an immediate impact on both our understanding of the geology and our ability to communicate it,” says Scott. “Seeing and comprehending in 3D gave clarity and meaning to the data and we were able to use 3D visualisations to communicate this to the client with clarity and confidence. Golder strongly believe that our engineering must preserve earth’s integrity. Using sophisticated, industry specific tools like Leapfrog Works means we can stay on track to achieve this.”

Pat McLarin, Product Manager of Leapfrog Works, says, “Leapfrog Works is designed to support civil engineering project workflows and can benefit all teams involved in them, from huge projects like the West Gate Tunnel Project to far smaller, routine projects. We are proud that Leapfrog Works has contributed to the key project outcomes of rapid modelling, visualisation and communicating risk in the successful first phase of this huge tunnelling project. We know that Golder has already gone on to use Leapfrog Works on several other projects and we look forward to working with them in the future and assisting with their ongoing ground engineering management needs.”