By Paul Colbert and Fiona Jeffreys

Advanced digital workflows helped cut costs by millions and boost sustainability at the PT Stargate nickel mining project in Indonesia.

Nickel is crucial for electric vehicle batteries and clean energy technologies. The International Energy Agency (IEA) predicts a 65% surge in demand for nickel by 2030 and Indonesia, one of the world’s largest suppliers, is positioned to meet a significant portion of future requirements. However, mining this critical metal is challenging due to the complex geological nature of nickel laterite deposits.

PT Stargate, a key player in Indonesia’s nickel mining industry, combines mining with geological exploration on their Sulawesi project.

Related content:

Muhammad Luthfi of SMG Consultants (SMGC) said they had explored various applications for geological modelling and data management but, “We always encountered limitations in workflow capabilities and had concerns about data integrity and confidentiality.”

Above: The Sulawesi project team at the pit view point

Right: A Sulawesi project team examining core samples in the core shed and the onsite Imago photo studio.

Optimising resource estimation from complex data

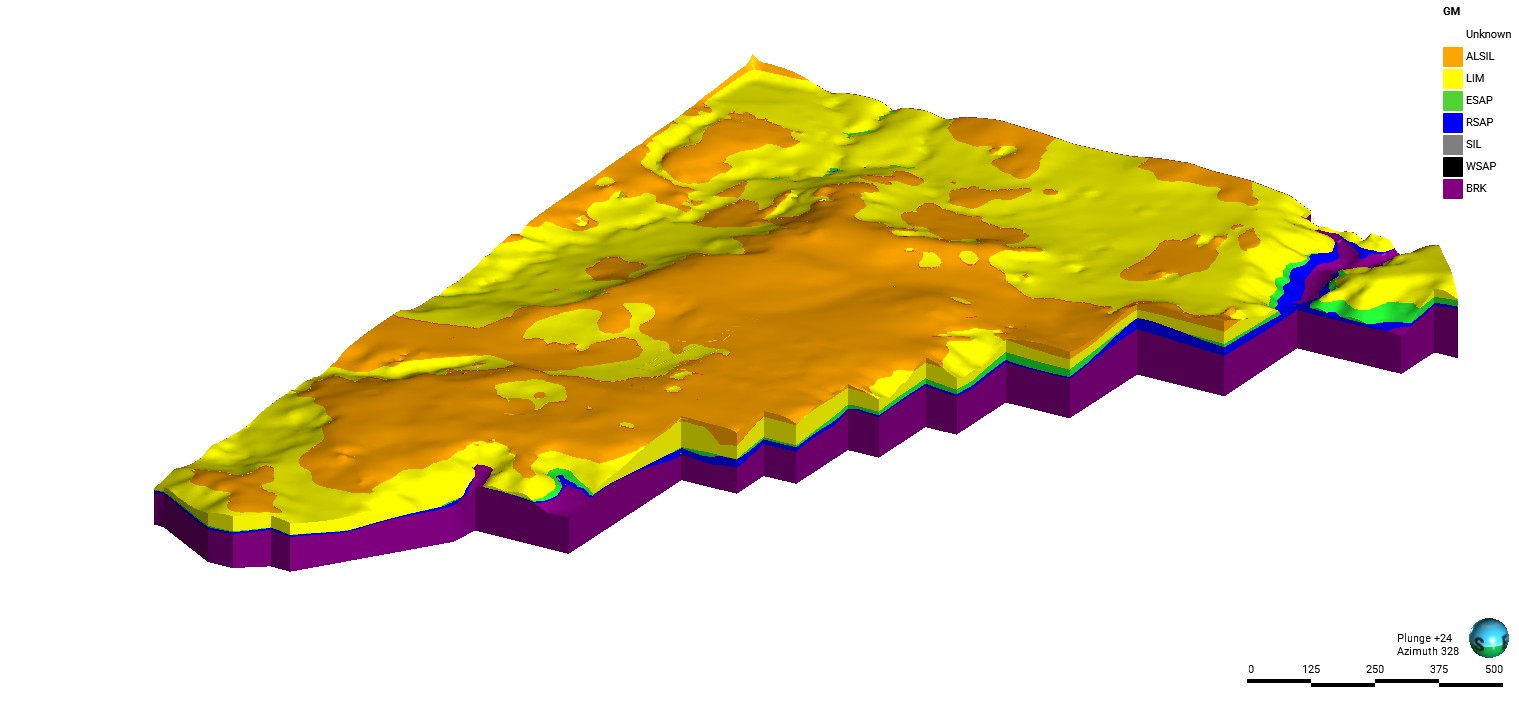

SMGC adopted Seequent’s MX Deposit, Imago, Leapfrog Geo and Leapfrog Edge solutions to address their challenges throughout this project. These solutions provided a secure, centralised repository for rig and sample data, integrated with advanced imaging capabilities, confident 3D modelling with Leapfrog Geo and robust resource estimation with Leapfrog Edge.

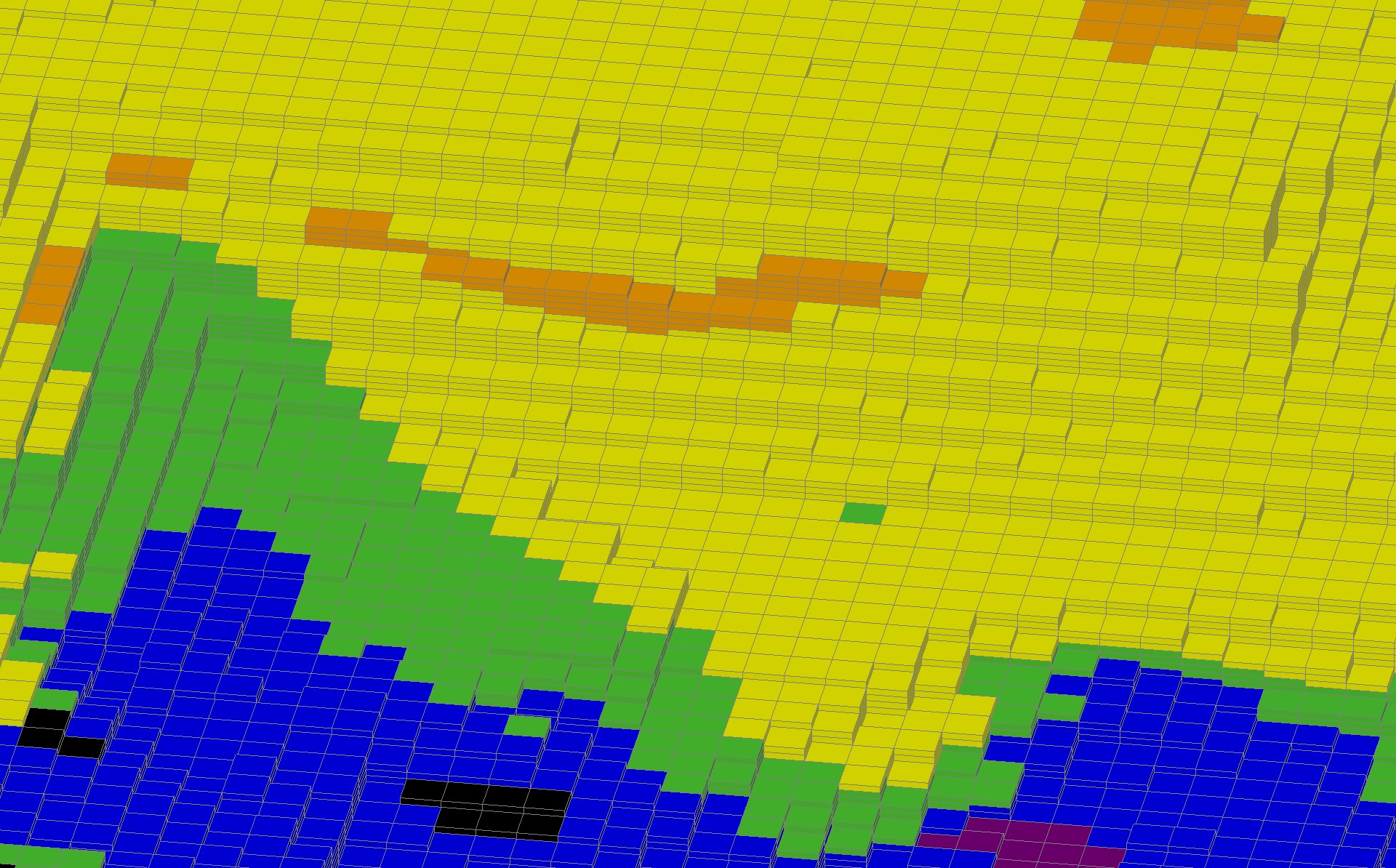

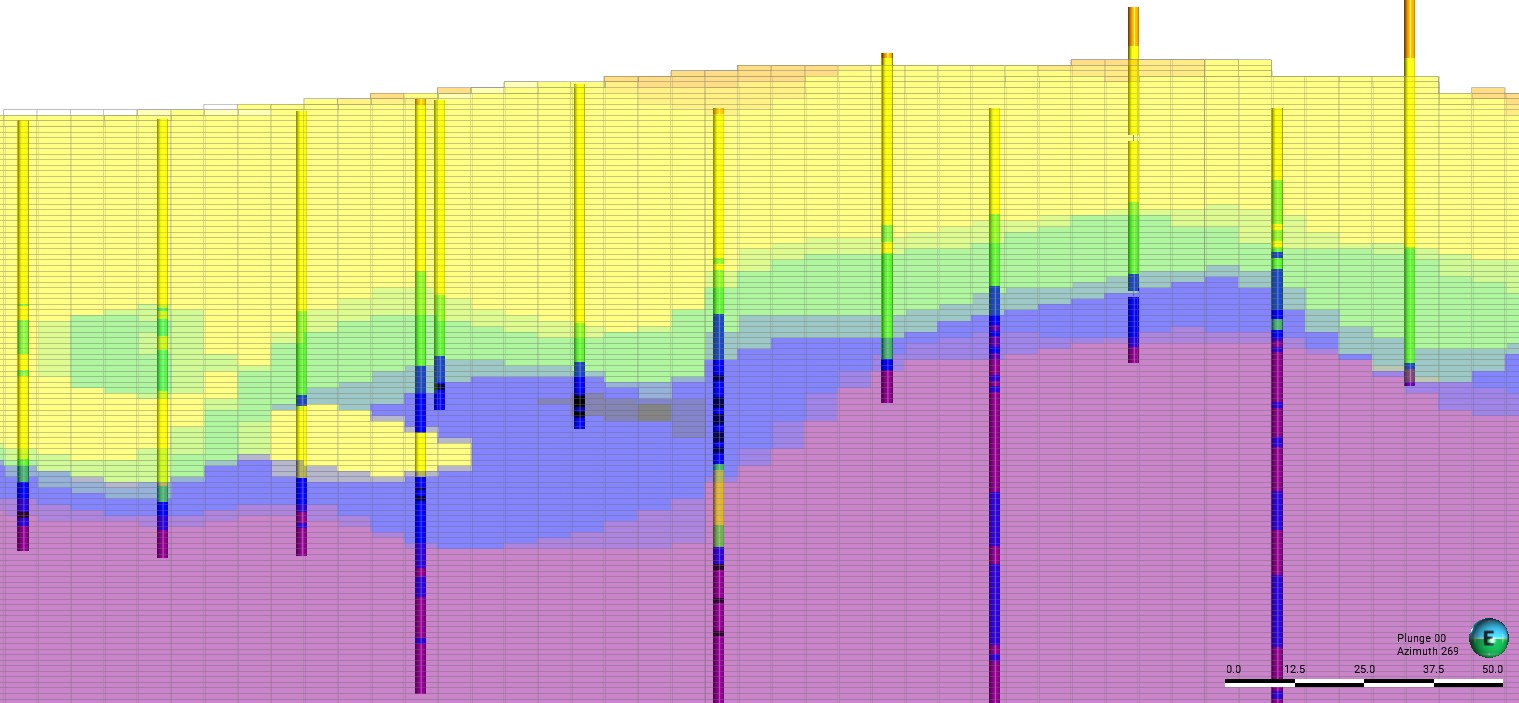

Pit face block model using Leapfrog Geo

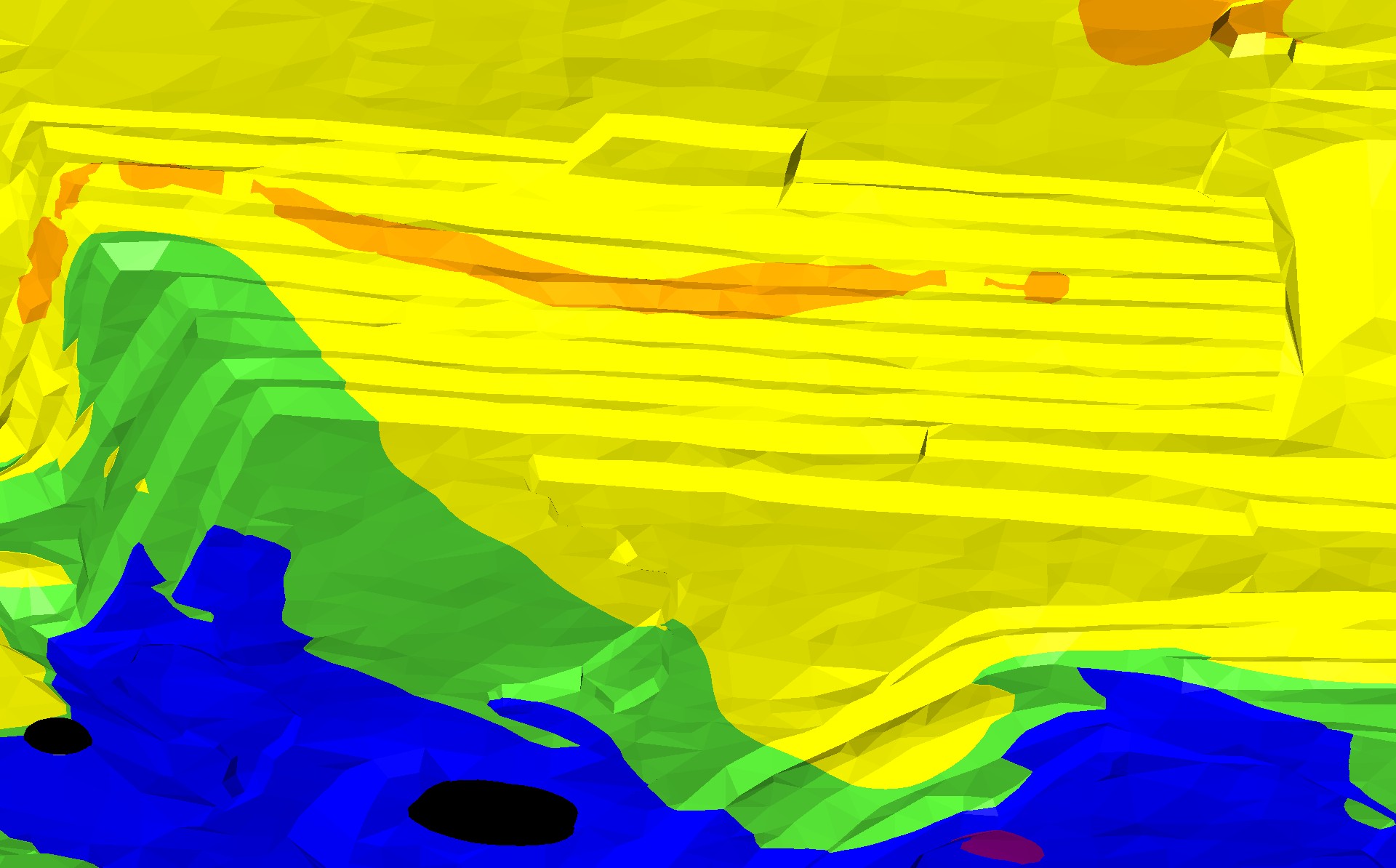

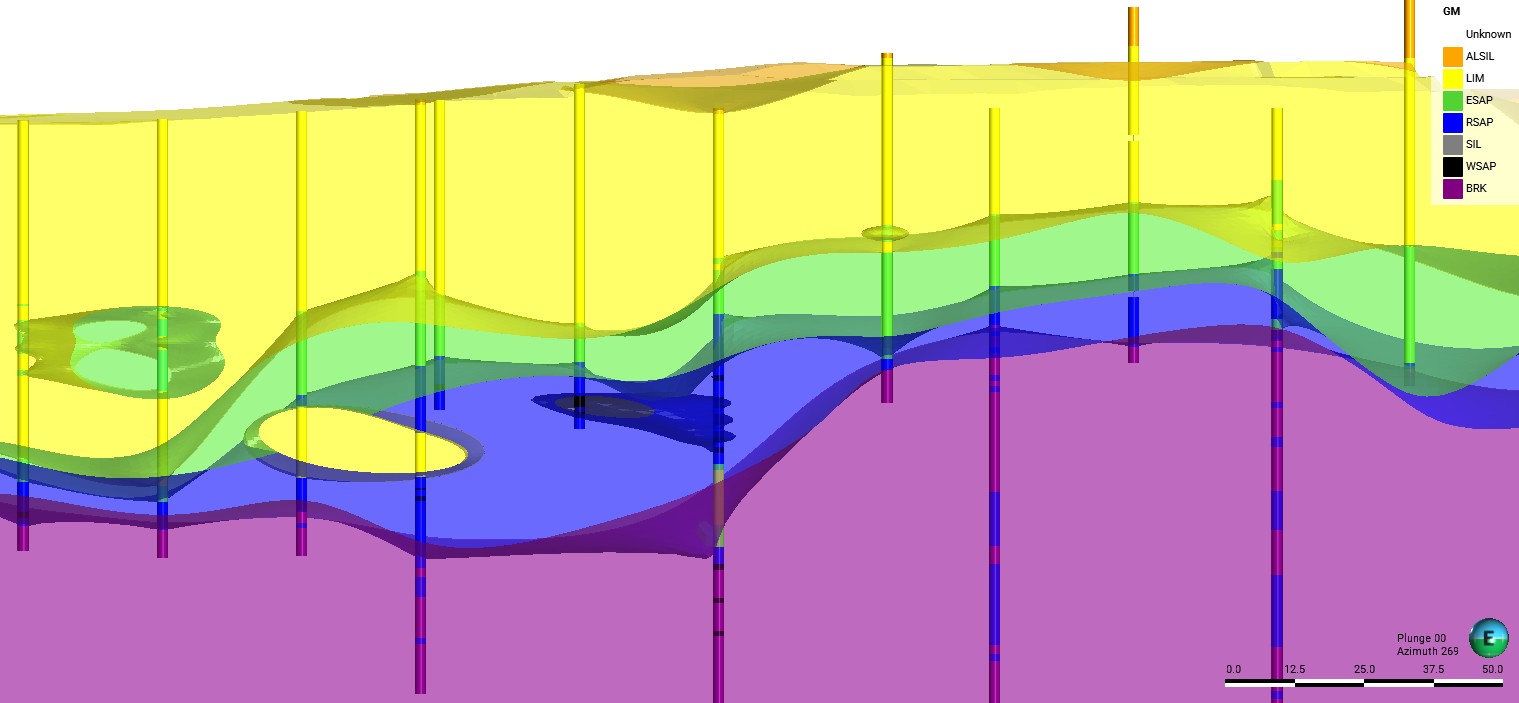

Pit face 3D model using Leapfrog Geo

“This integration enabled SMGC to develop accurate geological models from complex datasets, supporting optimised resource estimation and enhanced project workflows,” said Luthfi.

Previously, resource estimation took six weeks, with a week dedicated to cleaning up “messy spreadsheet data.” The most time-consuming step, geological domaining, could extend to three weeks, with large datasets requiring detailed review.

Aerial view of the pit face

A 3D geological model created in Leapfrog Geo

Applying machine learning to the data base

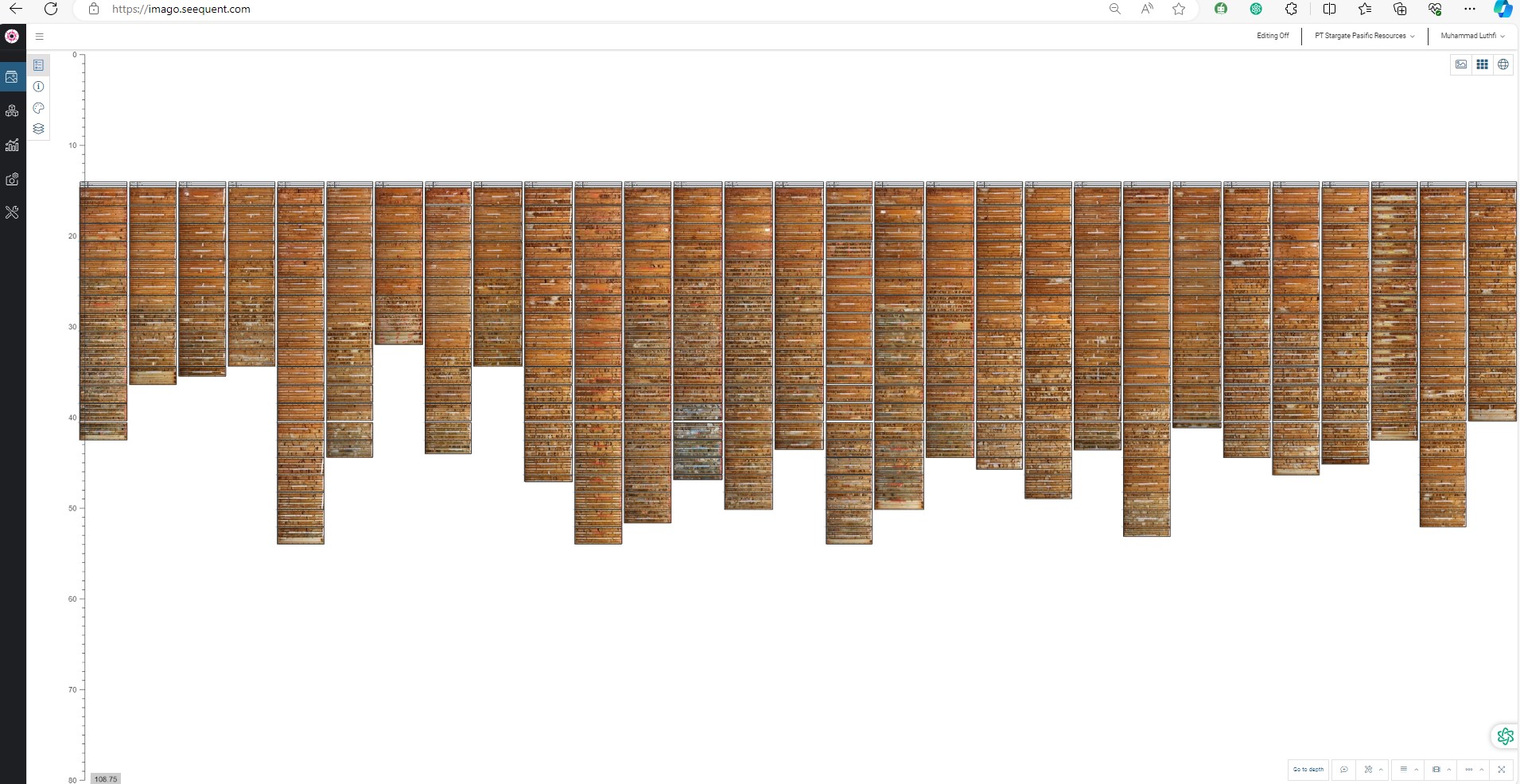

Seequent’s technology allowed all data, including databases, core photos, and modelling, to be stored and fully integrated within one platform.

This eliminated separate database validation and applied machine learning to the domaining process, reducing time spent from three weeks to two or three days. As a result, resource estimation dropped from six to one or two weeks.

These advances significantly impacted human resource development by reducing repetitive tasks by 75% and increasing employee productivity by 50%. Risks such as input errors, naming discrepancies, and data duplication were mitigated by 95% through the adoption of MX Deposit and Imago software.

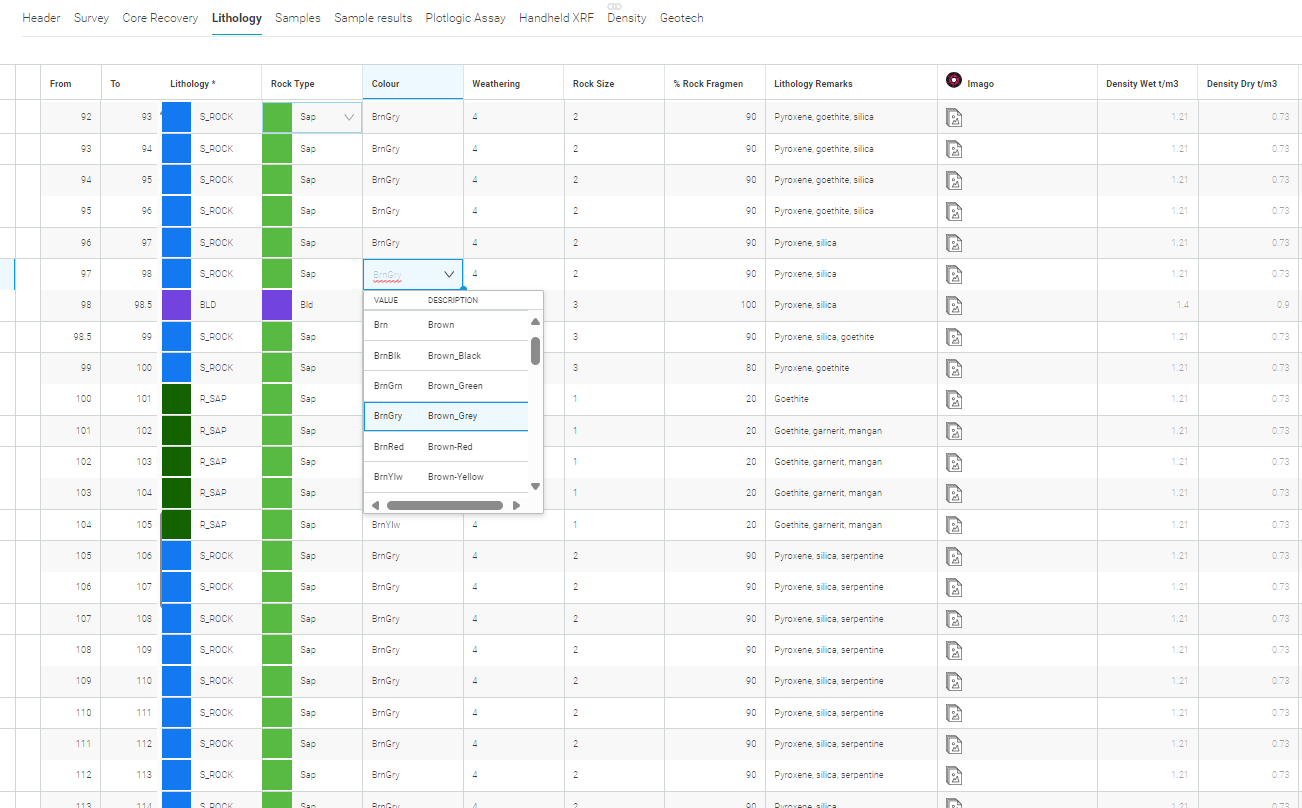

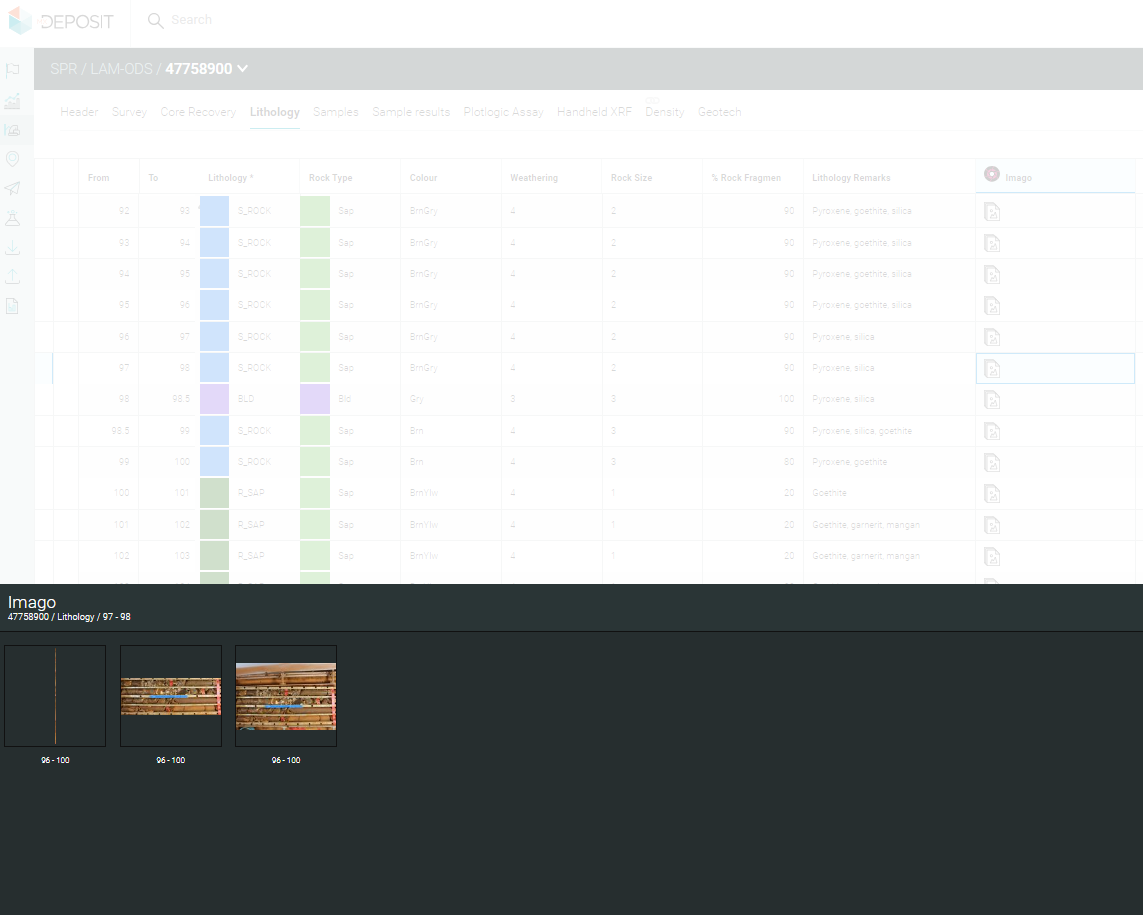

Above: Photographs of core, log in the Imago portal

Right : MX Deposit (top) and Imago (bottom) software integration for core logging and analysis

Leapfrog’s implicit modelling methods also reduced human subjectivity errors by up to 75%, significantly improving data integrity and modelling accuracy.

“Enhanced work efficiency has streamlined operational costs, driven increased company profits, and allowed funds to be allocated towards critical ESG-related areas,” said Muhammad Luthfi of SMG Consultants

Section Geological Model

Section Block Model

Aligning with global efforts to improve sustainability

Embracing digital technologies optimises not only mining operations but also positions organisations as leaders in more sustainable and efficient resource exploration and extraction.

“The extra accuracy of Leapfrog’s models enabled an 80% reduction in drilling needs, which helped minimise the project’s impact on natural habitats and contribute to overall environmental sustainability,” said Luthfi.

Efficiency gains in grade control are up to 10% better. Cloud database implementation has reduced paper usage entirely (and halved plastic usage), and indirectly enhanced mining operations by 25%.

$8m

cut from drilling costs

75%

reduction in repetitive tasks

50%

improvement in employee productivity

- Mitigating risks such as input errors, naming discrepancies, and duplicate data by 95% through MX Deposit and Imago software

- Reducing human subjectivity errors by 75% with Leapfrog’s implicit modelling methods, improving data integrity and modelling accuracy

- Reducing drilling costs by up to $8 million through increased confidence in geological models

- 80% reduction in drilling needs, minimising impact on natural habitats and contributing to environmental sustainability

- Improving grade control efficiency by 10%

- Reducing paper usage entirely and halving plastic usage with cloud database implementation

- Enhancing mining operations by 25% with digital technologies

By integrating advanced digital workflows into their Indonesian project, PT Stargate has transformed its operations, achieving significant cost savings, boosting productivity, and promoting environmental sustainability.

On a global scale, these improvements contribute to the sustainability of the nickel supply chain, essential for the stainless steel and battery industries worldwide.

YII submission summary video: Indonesia responsible mining